The Magic of Glass Batch Reactors

See Through Science: How Transparent Technology is Revolutionizing Labs Worldwide

Ever peeked into a chemistry lab and wondered about those fascinating glass contraptions with swirling liquids and bubbling reactions? Those, my friends, are glass batch reactors - the unsung heroes of modern laboratories. Forget the clunky, opaque steel tanks of the past. Today's scientists demand visibility, precision, and versatility. That's where glass batch reactors shine!

In this deep dive, we'll explore why these transparent powerhouses have become indispensable in industries ranging from pharmaceuticals to specialty chemicals. Whether you're a seasoned researcher or just science-curious, prepare to see laboratory technology in a whole new light.

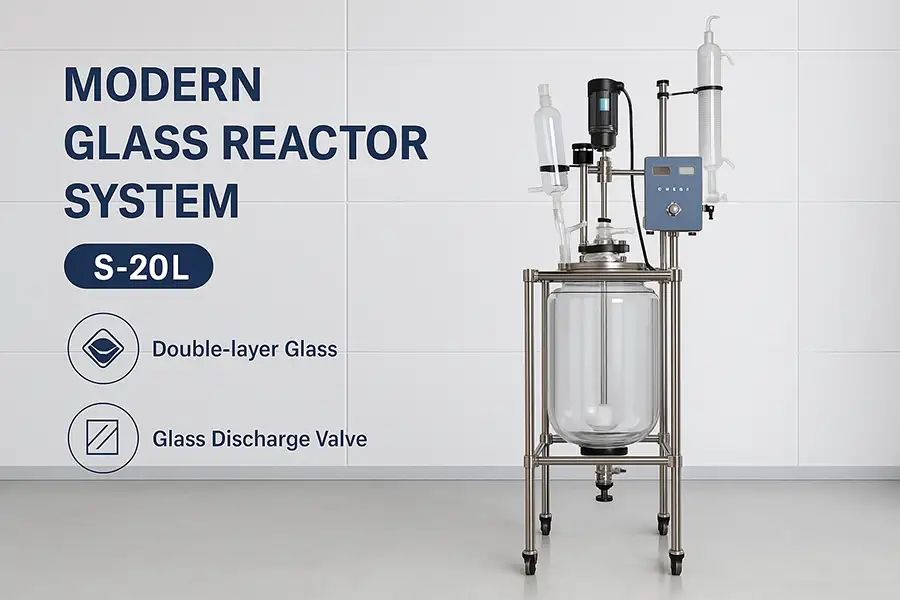

A modern glass batch reactor system in a research laboratory

What Exactly is a Glass Batch Reactor?

At its core, a glass batch reactor is a specialized vessel designed for chemical reactions, mixing, distillation, and other processes - all visible through transparent borosilicate glass. Unlike continuous reactors that constantly feed materials, batch reactors process fixed quantities at a time, giving researchers complete control over each reaction phase.

Why Glass?

Glass offers something no metal can: complete visibility. Researchers can monitor color changes, precipitation, phase separations, and gas evolution in real-time. According to a MIT study, visual monitoring improves experimental success rates by up to 40% compared to opaque systems. Plus, glass is chemically inert - it won't react with your precious compounds!

The Jacketed Advantage

Most modern glass reactors feature a "jacketed" design - essentially a double-walled vessel. This brilliant innovation allows temperature control fluids to circulate between the walls, heating or cooling reactions without direct contact. The result? Precision temperature control and safer operations.

Why should visibility matter in chemical reactions?

Great question! Visibility isn't just convenient - it's transformative. Seeing reactions in real-time allows scientists to:

Spot problems immediately (like unexpected precipitates or phase separations)

Make on-the-fly adjustments to temperature or mixing speed

Document the entire reaction process visually

Train new researchers by showing rather than telling

Reduce sampling frequency, minimizing contamination risks

In pharmaceutical research, this visibility has reduced process development time by up to 30% according to industry reports.

Why Labs Are Switching to Glass

Unmatched Visibility

Watch crystallization, color changes, and phase separations as they happen. No more guesswork or frequent sampling.

Chemical Resistance

Borosilicate glass withstands acids, bases, and solvents that would corrode metal reactors. Perfect for aggressive chemistry.

Modular Flexibility

Easily add condensers, dosing pumps, or temperature probes. Adapt your setup as research needs evolve.

Precision Control

Jacketed designs enable ±0.5°C temperature accuracy. Essential for sensitive reactions and reproducibility.

Scale-Up Confidence

Small-scale glass reactor results reliably predict large-scale manufacturing outcomes. Minimize pilot plant surprises.

Enhanced Safety

Visual monitoring reduces opening/reactor entry. Containment options prevent exposure to hazardous materials.

Can glass reactors handle high-pressure applications?

While standard glass reactors typically operate at atmospheric pressure, specialized designs can handle moderate pressure. For extreme conditions, high-pressure reactors with metal bodies are recommended. However, glass excels in:

Atmospheric distillations

Crystallization studies

Multi-step synthesis

Reactions requiring visual monitoring

For processes like decarboxylation that need both visibility and pressure, hybrid systems with glass viewports offer solutions.

Where Glass Reactors Shine

Glass batch reactors aren't just for academic curiosity - they're workhorses in critical industries:

Pharmaceuticals: Drug synthesis, polymorph screening, and process development

Specialty Chemicals: Catalyst testing, fine chemical production, and material synthesis

Agrochemicals: Pesticide formulation and fertilizer research

Food Science: Flavor compound extraction and ingredient development

Petrochemicals: Additive development and refining process simulation

Particularly in crystallization processes, the ability to monitor crystal formation in real-time makes glass reactors indispensable for controlling particle size and morphology.

Finding Your Perfect Fit: Glass Reactor Sizes

From small-scale screening to pilot plant preparations, glass reactors come in various sizes. Here's a quick guide:

| Reactor Size | Ideal For | Key Features | Options |

|---|---|---|---|

| 1L Jacketed | Initial screening, expensive materials | Minimal material usage, high visibility | Magnetic stirring, temperature control |

| 5L Jacketed | Process development, optimization | Balance of material economy & scalability | Full instrumentation capabilities |

| 10L Jacketed | Pilot batches, small production | Significant material output, robust design | Advanced control systems |

| 20-50L Systems | Small-scale manufacturing | Production quantities, GMP compliance | Automation, data logging |

| 100L+ Systems | Specialized production, niche markets | Industrial-scale glass processing | Custom engineering options |

For most R&D labs, the sweet spot is between 1L and 10L. The versatile glass reactor systems in this range offer the perfect balance of flexibility and output.

Cost Analysis: Penny Wise or Pound Foolish?

Saving Money Is The Last Word, And It Is Worth Investing In Buying!

Long-Term Value

Quality glass reactors last 10-15 years with proper care. That's decades of reliable service!

Contamination Costs

Glass prevents metal leaching that can ruin batches costing thousands in materials

Efficiency Gains

Visible reactions reduce trial cycles by 25-40% according to industry studies

Consider this: A single failed batch in pharmaceutical research can cost $50,000+ in materials alone. The right reactor pays for itself in avoided failures!

How do I choose between glass and stainless steel reactors?

The choice depends on your specific needs:

Choose Glass When:

Visual monitoring is essential

Working with corrosive materials

Conducting crystallization studies

Performing small-scale R&D

Choose Stainless Steel When:

High pressure/temperature required

Large-scale production

GMP manufacturing

Abrasive materials are used

Many labs maintain both: glass for development and stainless for scale-up. Hybrid systems are also available!

The Future is Clear: What's Next for Glass Reactors

The evolution continues! Emerging trends include:

AI Integration: Machine learning algorithms analyzing visual reaction data

Smart Sensors: Real-time monitoring of multiple parameters

Modular Scaling: Systems that grow with your research needs

Cloud Connectivity: Remote monitoring and control capabilities

Sustainable Designs: Energy-efficient systems with reduced footprints

According to industry forecasts, smart glass reactor adoption will grow 15% annually through 2030 as labs embrace Industry 4.0 principles.