Product Overview

The 10L jacketed glass reactor features a 10-liter capacity and dual-layer glass structure, specifically designed for medium-scale experiments and pilot production. The inner layer is used for stirring reaction solvents, while the jacket allows the circulation of heating or cooling media. Constructed with high borosilicate glass, it offers excellent physical and chemical properties and can operate within a broad temperature range from 200°C to -120°C (requires a low-temperature pump or oil bath). The 10L glass reactor is an ideal solution for modern chemical experiments, biopharmaceutical applications, and new material synthesis.

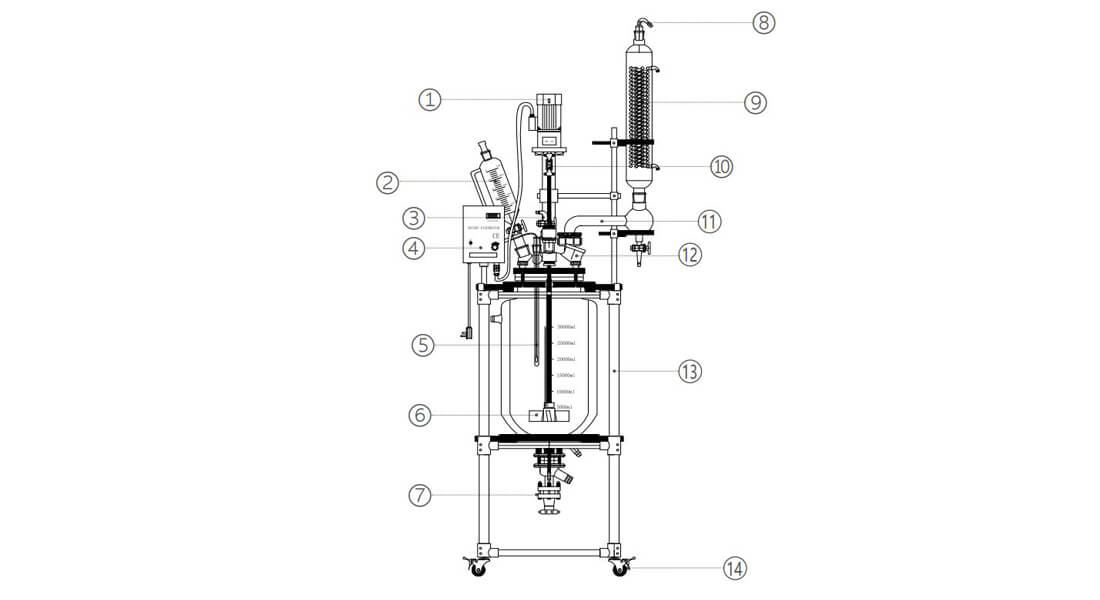

Component Structure

Part | Part | ||

1 | Motor | 8 | Air Extraction Head |

2 | Constant Pressure Funnel | 9 | Condenser |

3 | Release Valve | 10 | Universal Joint |

4 | Speed control Box | 11 | Return Elbow |

5 | Thermowell | 12 | Solid Feed Port |

6 | PTFE Stirring Blades | 13 | 304 Stainless Steel Frame |

7 | Discharge Valve | 14 | Brake Casters |

Product Features

High Transparency Glass: The 10L jacketed glass reactor is made of premium borosilicate glass, offering high transparency for easy monitoring of the experimental process.

Precise Stirring Speed Control: This 10L glass reactor provides precise control over stirring speed, ensuring uniform mixing of materials.

High Operational Efficiency: Equipped with an efficient heating/cooling system, the reactor ensures quick and accurate temperature control. The PID temperature control algorithm minimizes energy waste and improves production efficiency.

Multiple Safety Protections: Includes protections against overcurrent, grounding faults, and overheating, ensuring a safe experimental process.

Ease of Cleaning and Maintenance: The five-port reactor lid design includes a large opening for easy cleaning and standard joints for assembling reflux, distillation, or synthesis devices.

Applications

Pharmaceutical Industry: The 10L jacketed glass reactor is widely used in the pharmaceutical sector for synthesis reactions, distillation, separation, and filtration, creating an ideal environment for synthesizing diverse target compounds.

Chemical Industry: This 10L glass reactor can be applied to various chemical reactions, including high-temperature and low-temperature processes, as well as those requiring precise temperature control.

Biological Products: The 10L jacketed glass reactor is also suitable for the synthesis of biological products, such as microbial cultivation, biopharmaceutical engineering, and enzyme reactions, providing a stable experimental environment and reliable data support.

New Material Synthesis: In the field of new material synthesis, the 10L glass reactor serves as a pilot or production device for fine chemicals, biopharmaceuticals, and advanced materials.

Scientific Research: In research laboratories, this reactor is used for conducting a variety of chemical experiments, including but not limited to chemical synthesis, environmental studies, and life sciences research.

After-Sales Service

Technical Support:

Assistance with equipment installation, commissioning, and operational training.

Troubleshooting and solutions to ensure normal operation.

Routine Maintenance:

Regular maintenance and upkeep services.

Ensuring the equipment operates at optimal performance.

Custom Services:

Customizable components and functional options based on customer needs.

Meeting diverse requirements for experiments and production.

The 10L jacketed glass reactor stands out for its exceptional performance, durability, efficiency, and adaptability, making it an indispensable choice for medium-scale experimental setups.

FAQ

Question: What causes abnormal noise during the operation of a 10L jacketed glass reactor?

Answer: The noise could result from friction between the agitator and the reactor wall, bearing damage, or motor issues. Check the position of the agitator and the condition of the bearings, and adjust or replace components as necessary.

Question: What should I do if the motor temperature is too high?

Answer: If the motor temperature exceeds 40°C above room temperature, it is normal. However, if it becomes excessively high, it may be due to overloading. Stop the reactor and manually rotate the motor shaft to check for difficulty in movement. If it is difficult, clean the seal ring and the contact area with the glass shaft, and apply vacuum grease.

Question: What should I check if the vacuum suddenly disappears?

Answer: Inspect the glass components for cracks and check the switches for damage. If cracks are found in the glass parts, they need to be replaced. If a switch is broken, it must be replaced accordingly.

Product Parameters

Model | Power(W ) | Stirring Speed(rmp) | Diameter | Capacity(L) | Power Supply | Motor Torque(g/cm) |

S-1L | 60 | 0~600(Max.1300) | 12 | 1 | 220V 50/60 Hz | 2000 |

S-2L | 60 | 0~600(Max.1300) | 12 | 2 | 220V 50/60 Hz | 2400 |

S-3L | 60 | 0~600(Max.1300) | 12 | 3 | 220V 50/60 Hz | 2400 |

S-5L | 60 | 0~600(Max.1300) | 12 | 5 | 220V 50/60 Hz | 4800 |

S-10L | 120 | 0~600(Max.1300) | 12 | 10 | 220V 50/60 Hz | 1000 |

S-20L | 120 | 0~600(Max.1300) | 12 | 20 | 220V 50/60 Hz | 1200 |

S-30L | 120 | 0~600(Max.1300) | 12 | 30 | 220V 50/60 Hz | 1200 |

S-50L | 120 | 0~600(Max.1300) | 12 | 50 | 220V 50/60 Hz | 1500 |

S-100L | 250 | 0~600(Max.1300) | 15 | 100 | 220V 50/60 Hz | 3000 |

Model | Power(W ) | Stirring Speed(rmp) | Diameter |

S-1L | 60 | 0~600(Max.1300) | 12 |

S-2L | 60 | 0~600(Max.1300) | 12 |

S-3L | 60 | 0~600(Max.1300) | 12 |

S-5L | 60 | 0~600(Max.1300) | 12 |

S-10L | 120 | 0~600(Max.1300) | 12 |

S-20L | 120 | 0~600(Max.1300) | 12 |

S-30L | 120 | 0~600(Max.1300) | 12 |

S-50L | 120 | 0~600(Max.1300) | 12 |

S-100L | 250 | 0~600(Max.1300) | 15 |

Contact Us Now

WhatsApp:

Email:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China