Product Overview

The 5L glass reactor is specifically designed to meet the needs of small-scale pilot production and fine chemical synthesis in fields such as chemistry, pharmaceuticals, food, and new materials. Made from high borosilicate glass, it features excellent corrosion resistance and transparency, adapting to a wide variety of reaction conditions. The 5L jacketed glass reactor is widely applied in processes like synthesis, hydrolysis, esterification, and polymerization, making it an ideal choice for research laboratories and small-scale production lines.

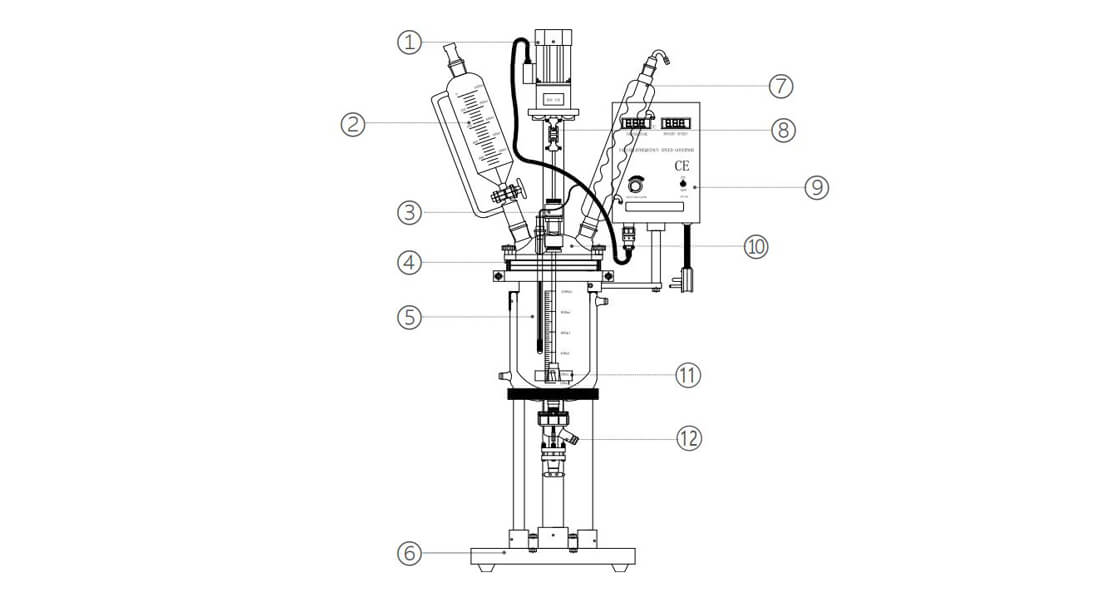

Component Structure

Part | Part | ||

1 | Motor | 7 | Condenser |

2 | Constant Pressure Funnel | 8 | Universal Joint |

3 | Mechanical Sealing | 9 | Speed Control Box |

4 | Flange | 10 | Kettle Cover |

5 | Kettle Body | 11 | Ptfe Stirring Blades |

6 | 304 Bottom Plate | 12 | Discharge Valve |

Product Features

Jacketed Design: The 5L glass reactor and 5L jacketed glass reactor both use a dual-layer jacket design, which increases heat exchange area and optimizes the flow path of coolant or heating media, ensuring more precise and faster temperature control.

Efficient Heating/Cooling System: Equipped with a heating rod or circulation heating/cooling device, the 5L jacketed glass reactor responds quickly to temperature changes, reducing energy waste and improving production efficiency.

Insulation Layer: An insulation layer on the exterior of the jacket minimizes heat loss and maintains stability within the reaction system.

Smart Temperature Control Algorithm: Built-in PID temperature control automatically adjusts heating/cooling power, ensuring smooth transitions and precise temperature regulation.

Variable Frequency Control: With variable frequency control, digital display, and AC induction motor, the 5L glass reactor and 5L jacketed glass reactor operate safely, without brushes or sparks, and in low-noise conditions.

Application Scenarios

The 5L glass reactor and 5L jacketed glass reactor demonstrate exceptional flexibility and adaptability across various industrial applications. Below are some of their major application areas, along with specific uses and advantages:

Drug Development and Pharmaceutical Industry

Synthesis of Drug Intermediates: In new drug research, the 5L jacketed glass reactor is commonly used to synthesize various drug intermediates. Its precise temperature control and efficient stirring system ensure high yields and quality of chemical reactions.

Crystallization of Pharmaceuticals: Through precise temperature regulation, the 5L glass reactor can optimize the crystallization process of drugs, enhancing product purity and stability.

Fine Chemical Synthesis

Polymer Preparation: The 5L glass reactor provides a stable reaction environment for polymer synthesis, ensuring uniform growth of polymer chains, making it suitable for preparing various high-performance polymer materials.

Flavor and Food Additive Synthesis: In the food industry, the 5L jacketed glass reactor is frequently used to synthesize natural or synthetic flavors and food additives, ensuring product safety and flavor quality.

Material Science Research

Nanomaterial Synthesis: Both the 5L glass reactor and 5L jacketed glass reactor are excellent tools for synthesizing various nanomaterials, such as nanoparticles and nanofibers, providing foundational materials for materials science research.

Composite Material Production: These reactors are used in the preparation of composite materials, ensuring uniform mixing and reaction of different components to achieve superior material performance.

Other Applications

Chemical Engineering and Process Optimization: In chemical engineering, the 5L jacketed glass reactor helps optimize reaction conditions, improving production efficiency and product quality.

Education and Training: In chemical education and training, the 5L glass reactor can be used to demonstrate chemical reaction processes, aiding students in understanding chemical principles and operational techniques.

Heating Precautions

Do not use an electric furnace or open flame to heat the 5L glass reactor directly; use a dedicated heating circulation bath for safe heating.

When using a heating circulation bath, it is recommended to use low-risk heating media, such as 2A silicone oil.

Before starting the heating process, first activate the circulation pump, and gradually increase the temperature while the oil is circulating.

Avoid direct contact with the reactor body when it reaches high temperatures to prevent burns. Allow the 5L jacketed glass reactor to cool naturally after the experiment; do not cool it rapidly to prevent damage caused by thermal shock.

Before using the heating circulation bath, ensure water or oil is added to the bath. Turn off the power supply after use. Do not touch heated media directly to avoid burns.

The water level in the heating circulation bath must cover the PT100 thermocouple probe by 3–5 cm. Regularly check and replenish water to prevent dry heating (dry heating is strictly prohibited). If liquid dries up, immediately cut off the power and wait for the heating element to cool naturally before refilling.

FAQ

Q: What should I do if the stirrer of the 5L glass reactor stops working?

A: Check if the motor driver is functioning properly, such as whether electrical connections are loose or the voltage is stable. If necessary, replace faulty components. Additionally, check the lubrication of the stirrer bearings and apply oil or replace the bearings if abnormal conditions are detected.

Q: How can I resolve excessive pressure in the 5L jacketed glass reactor?

A: First, check for blockages or improperly sealed valves. If all passages are clear and the issue persists, reduce the amount of reactants or increase the reactor volume while improving ventilation.

Q: How can I fix inaccurate temperature control in the 5L glass reactor?

A: Verify the correct installation and connection of the temperature sensor. If the problem persists, recalibrate or replace the temperature controller. Also, check whether the heater is functioning properly and repair or replace it as needed.

Product Parameters

Model | Power(W ) | Stirring Speed(rmp) | Diameter | Capacity(L) | Power Supply | Motor Torque(g/cm) |

S-1L | 60 | 0~600(Max.1300) | 12 | 1 | 220V 50/60 Hz | 2000 |

S-2L | 60 | 0~600(Max.1300) | 12 | 2 | 220V 50/60 Hz | 2400 |

S-3L | 60 | 0~600(Max.1300) | 12 | 3 | 220V 50/60 Hz | 2400 |

S-5L | 60 | 0~600(Max.1300) | 12 | 5 | 220V 50/60 Hz | 4800 |

S-10L | 120 | 0~600(Max.1300) | 12 | 10 | 220V 50/60 Hz | 1000 |

S-20L | 120 | 0~600(Max.1300) | 12 | 20 | 220V 50/60 Hz | 1200 |

S-30L | 120 | 0~600(Max.1300) | 12 | 30 | 220V 50/60 Hz | 1200 |

S-50L | 120 | 0~600(Max.1300) | 12 | 50 | 220V 50/60 Hz | 1500 |

S-100L | 250 | 0~600(Max.1300) | 15 | 100 | 220V 50/60 Hz | 3000 |

Model | Power(W ) | Stirring Speed(rmp) | Diameter |

S-1L | 60 | 0~600(Max.1300) | 12 |

S-2L | 60 | 0~600(Max.1300) | 12 |

S-3L | 60 | 0~600(Max.1300) | 12 |

S-5L | 60 | 0~600(Max.1300) | 12 |

S-10L | 120 | 0~600(Max.1300) | 12 |

S-20L | 120 | 0~600(Max.1300) | 12 |

S-30L | 120 | 0~600(Max.1300) | 12 |

S-50L | 120 | 0~600(Max.1300) | 12 |

S-100L | 250 | 0~600(Max.1300) | 15 |

Contact Us Now

WhatsApp:

Email:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China