Product Overview

The CJF high pressure autoclave reactor is a stirring reaction device designed for chemical reactions under high temperature and high pressure conditions, particularly suited for gas-liquid, liquid-liquid, liquid-solid, or gas-liquid-solid three-phase reactions. The design pressure of the CJF high pressure autoclave reactor can reach up to 22 MPa, with a design temperature as high as 350°C, making it ideal for chemical reactions in high-pressure and high-temperature environments. It is widely used in fields such as petroleum, chemical engineering, organic synthesis, and polymer material polymerization, especially for reactions like sulfurization, fluorination, hydrogenation, and oxidation.

Product Features

High Pressure Tolerance:

The CJF high pressure autoclave reactor is designed to withstand high working pressures, typically able to handle several megapascals, making it suitable for chemical reactions requiring high pressure environments.

Temperature Control:

The reactor operates at high temperatures, with a design temperature of up to 350°C or higher, making it suitable for synthesis and reactions that require high-temperature conditions.

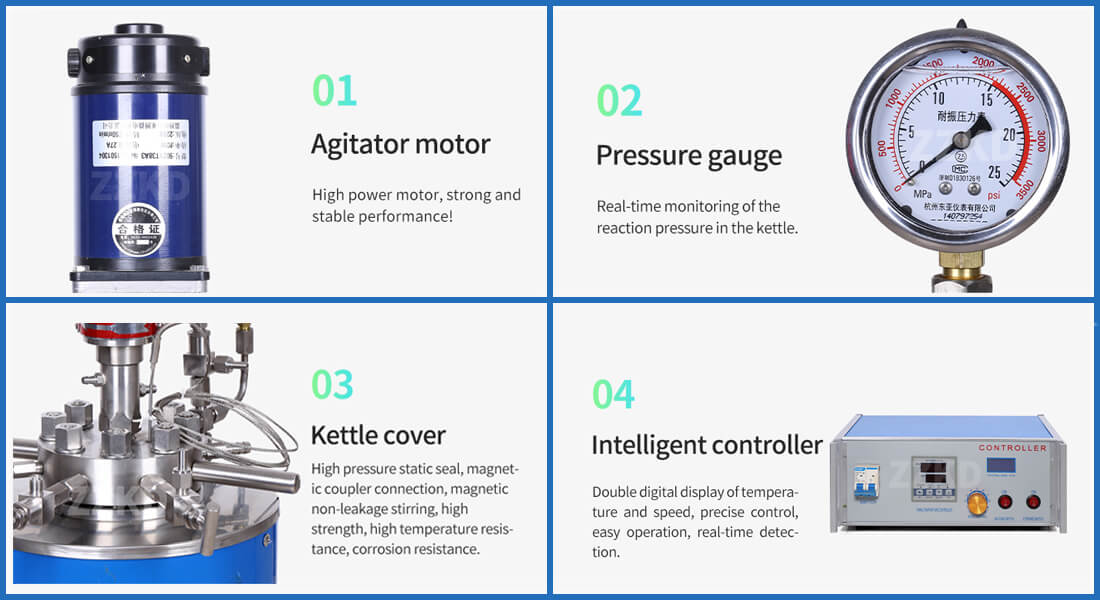

Magnetic Stirring:

The high pressure autoclave reactor uses magnetic stirring to eliminate the wear and leakage issues associated with mechanical seals, ensuring the safety and reliability of the stirring process.

Material Selection:

The reactor body is typically made of stainless steel or other corrosion-resistant materials, suitable for reactions involving various chemical media.

Heating Methods:

The reactor offers flexible heating options, including electric heating, steam heating, or hot water heating, depending on the specific heating needs of the process.

Customization Service:

The CJF high pressure autoclave reactor can be customized according to the specific requirements of the client to meet unique process needs.

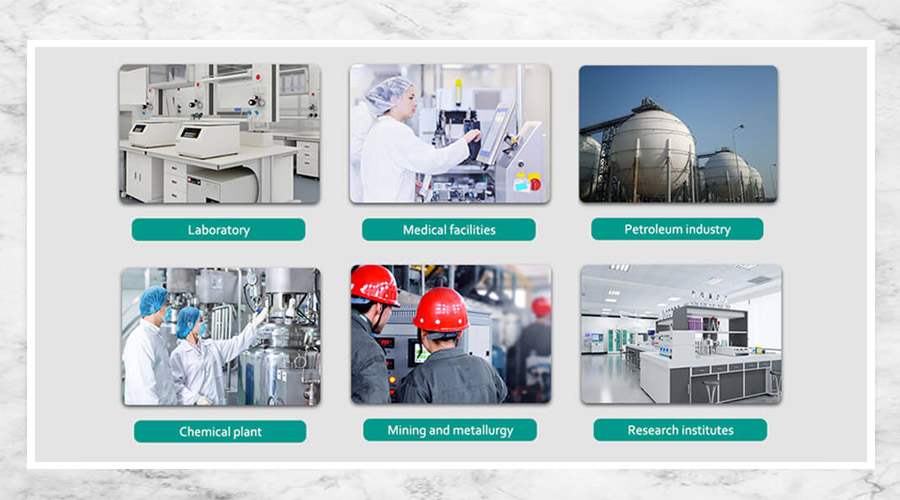

Application Areas

Petrochemical Industry:

The CJF high pressure autoclave reactor is ideal for sulfurization, fluorination, hydrogenation, and other reactions in the petrochemical industry, particularly for chemical reactions under high-temperature and high-pressure conditions.

Organic Synthesis:

In organic synthesis, the reactor is used for various gas-liquid, liquid-liquid, liquid-solid, or gas-liquid-solid three-phase chemical reactions, enhancing mass and heat transfer processes.

Schools and Laboratories:

The reactor is also suitable for research and experimental use in schools, laboratories, and other scientific research institutions.

Chemicals and Fine Chemicals:

The CJF high pressure autoclave reactor is applied in the chemical and fine chemical industries for various chemical reactions, providing precise temperature and pressure control.

Biopharmaceuticals:

In the biopharmaceutical industry, the high pressure autoclave reactor is used for high-pressure reactions during drug synthesis, ensuring both safety and efficiency.

New Materials Synthesis:

The reactor can be used for high-temperature and high-pressure reactions in new material synthesis, such as the preparation of new energy materials.

Working Principle

The working principle of the CJF high pressure autoclave reactor is based on its ability to withstand high-pressure environments, allowing chemical reactions to take place inside a sealed vessel. External heating methods (such as electric heating, steam heating, etc.) provide the necessary heat, while the magnetic stirrer ensures uniform mixing of the materials inside the reactor. This guarantees adequate contact between reactants, promoting efficient chemical reactions. High pressure enhances reaction rates, increases the solubility of raw materials, and facilitates specific chemical reactions. Safety devices such as safety valves and pressure gauges ensure safe operation by preventing overpressure.

Precautions

Use in Designated Locations with Operating Instructions:

The CJF high pressure autoclave reactor should be used in designated areas, and operations must strictly follow the provided operating instructions.

Check Equipment Parameters:

Before use, check the test pressure, working pressure, and maximum allowable temperature on the main reactor body to ensure operation within safe parameters.

Check Safety Devices:

Ensure that the safety valve and other safety devices are regularly inspected and meet the required standards.

Correct Placement of Thermometer:

During operation, ensure that the thermometer is accurately inserted into the reaction solution for proper temperature measurement.

Symmetrical Tightening of Bolts:

When closing the flange cover, bolts at diagonal points should be tightened in pairs evenly and sequentially.

Avoid Standing in Hazardous Areas:

When measuring instruments break, the glass surface may shatter on both sides. Do not stand in these potentially dangerous areas during operation.

After-Sales Service

Professional Experience:

Our company has years of experience in the production and sale of high pressure autoclave reactors, with a deep understanding of the industry and extensive knowledge.

High-Quality Products:

We manufacture our products with high-quality materials, adhering to international quality standards to ensure durability and reliability.

Customization Services:

We offer customized services, able to design and manufacture high pressure autoclave reactors with specific specifications and functions according to customer needs.

Technological Innovation:

We continuously invest in research and development, adopting the latest technologies and innovative designs to improve product efficiency and performance.

Comprehensive After-Sales Support:

We offer full after-sales services, including installation guidance, operation training, and troubleshooting, ensuring that customers can use the products effectively.

Global Network:

Our extensive global distribution network enables us to respond quickly to the needs of customers in different regions.

Safety and Compliance:

Our products comply with international safety and environmental standards, ensuring user safety during operation.

FAQ

Q: What materials are used in the construction of the CJF high pressure autoclave reactor?

A: The material for the CJF high pressure autoclave reactor is selected based on the chemical properties of the reaction medium and the required temperature and pressure. Common materials include stainless steel (such as 316L), Hastelloy, and titanium alloys to ensure corrosion resistance and structural strength.

Q: What chemical reactions is the CJF high pressure autoclave reactor suitable for?

A: The CJF high pressure autoclave reactor is ideal for stirring reactions involving flammable, explosive, toxic, or highly permeable chemicals, especially in petroleum, chemical, organic synthesis, polymer material polymerization, and food processes such as sulfurization, fluorination, oxidation, and others.

Q: What heating methods are available for the CJF high pressure autoclave reactor?

A: The CJF high pressure autoclave reactor offers several heating methods, including electric heating, liquid heating, and a combined electric-liquid heating model, providing flexibility based on customer needs.

Q: How safe is the CJF high pressure autoclave reactor?

A: The CJF high pressure autoclave reactor is equipped with safety valves featuring rupture membranes, which have minimal deviation and fast discharge rates. These safety features ensure reliability. Additionally, the reactor’s valves are designed to be needle valves with a reciprocating closure, ensuring a reliable and durable seal, with proper installation for smooth venting and no dead spots.

Product Parameters

Model | Capacity (L) | Setting Pressure (MPa) | Setting Temperature (℃) | Heating Power (kW) | Stirring Torque (N. cm) | Voltage (V/Hz) |

CJF-5 | 5 | 22 | 350 | 4 | 120 | 220 50/60 |

CJF-10 | 10 | 22 | 350 | 7 | 120 | 220 50/60 |

CJF-20 | 20 | 22 | 350 | 10 | 120 | 220 50/60 |

CJF-30 | 30 | 22 | 350 | 12 | 120 | 220 50/60 |

Model | Capacity (L) | Setting Pressure (MPa) | Setting Temperature (℃) |

CJF-5 | 5 | 22 | 350 |

CJF-10 | 10 | 22 | 350 |

CJF-20 | 20 | 22 | 350 |

CJF-30 | 30 | 22 | 350 |

Contact Us Now

WhatsApp:

Email:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China