Product Overview

The FCF high pressure chemical reactor is specially designed for chemical reactions under high-pressure conditions. It is ideal for stirring reactions involving flammable, explosive, toxic, valuable, and other highly permeable chemical media. This reactor is perfect for reactions like sulfurization, fluorination, hydrogenation, and oxidation, providing a leak-proof reaction vessel. The design pressure of the FCF high pressure chemical reactor can reach up to 22 MPa, with a design temperature up to 350°C, making it suitable for reactions at high pressures and temperatures. The FCF high pressure chemical reactor is available in multiple volume sizes, ranging from 0.1L to 100L, to meet different experimental and production needs.

Product Features

High Pressure Tolerance:

The FCF high pressure chemical reactor is designed to withstand high working pressures, typically handling pressures up to several tens of megapascals, making it suitable for chemical reactions in high-pressure environments.

Temperature Control:

The reactor can handle high working temperatures, with a design temperature of up to 350°C or higher, making it suitable for chemical reactions that require high-temperature conditions.

Superior Material Selection:

The reactor body is typically made of stainless steel or other corrosion-resistant materials to accommodate various chemical media and reaction conditions.

User-Friendly Operation:

With a reasonable structural design, the FCF high pressure chemical reactor is easy to operate, maintain, and clean.

Flexible Heating Methods:

The reactor offers multiple heating options, such as electric heating, steam heating, or hot water heating, to accommodate different heating requirements.

Customization Services:

Custom solutions are available for the FCF high pressure chemical reactor, designed to meet specific process requirements as per customer needs.

Application Areas

Petrochemical Industry:

The FCF high pressure chemical reactor is ideal for sulfurization, fluorination, hydrogenation, oxidation, and other reactions in the petroleum, chemical, and organic synthesis industries, providing a leak-proof solution for these processes.

Polymer Material Polymerization:

In the field of polymer material polymerization, the FCF high pressure chemical reactor can fully stir at high pressure, vacuum, and temperature, enhancing mass transfer and heat transfer processes.

Laboratory Research:

The FCF series laboratory magnetic stirring reactors are suitable for gas-liquid, liquid-liquid, liquid-solid, or gas-liquid-solid three-phase chemical reactions in laboratory settings.

Flammable and Explosive Media Reactions:

The reactor is especially suitable for reactions involving flammable, explosive, toxic, valuable, and other highly permeable chemical media.

High-Temperature Vacuum Stirring Reactions:

The FCF high pressure chemical reactor can perform stirring reactions at both high and low temperatures under vacuum conditions, ideal for processes that require negative pressure operation.

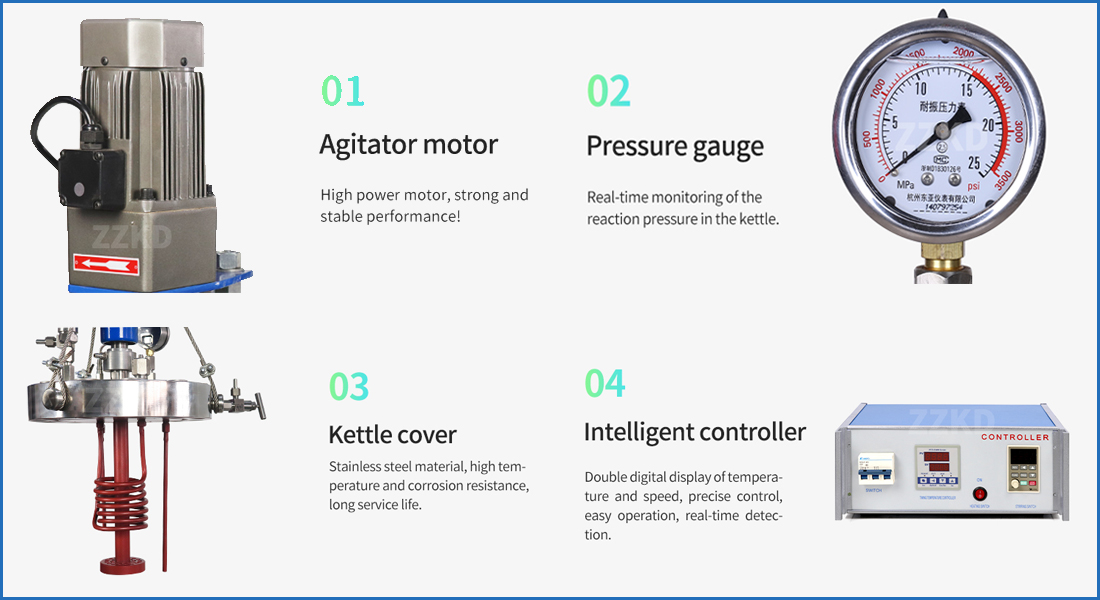

Working Principle

The FCF high pressure chemical reactor works by performing chemical reactions inside a sealed container. External heating methods (such as electric heating, steam heating, etc.) provide the necessary heat, while the magnetic stirrer ensures uniform mixing of materials inside the reactor. The magnetic stirrer transmits torque through a magnetic field, eliminating the need for mechanical seals, and thus avoiding leakage problems associated with traditional stirring methods, ensuring safety during the stirring process. The high pressure environment enhances reaction rates, increases the solubility of raw materials, and facilitates specific chemical reactions. Safety valves, pressure gauges, and other devices are incorporated to ensure pressure control during operation, preventing overpressure situations.

Precautions

Symmetrical Tightening of Nuts:

When closing the reactor, the nuts at diagonal points should be tightened symmetrically, with gradual and evenly distributed force to prevent improper tightening.

Slow Inlet and Outlet of Gas:

Gas filling and venting should be performed slowly to avoid solvent spillage.

Sealing Check:

Special attention should be paid to the protection and replacement cycle of the sealing ring to ensure its sealing performance remains intact.

Gradual Heating:

When using the reactor for heating reactions, heating should be gradual. Do not directly expose the reactor to a high-temperature environment, as this could lead to overpressure.

Safety Protection:

Operators should wear necessary protective equipment such as goggles, gloves, and protective clothing to prevent chemical splashes or burns from high temperatures.

Follow Operating Procedures:

Strictly adhere to the operating procedures for the reactor and do not change the reaction conditions (such as temperature, pressure, etc.) without proper authorization, to avoid equipment damage or personal injury.

After-Sales Service

Professional Experience:

Our company has extensive experience in the production and sale of high pressure chemical reactors, with a deep understanding of the industry and broad knowledge base.

High-Quality Products:

We use high-quality materials in manufacturing our products, strictly following international quality standards to ensure durability and reliability.

Customization Services:

We offer customized solutions, able to design and manufacture high pressure chemical reactors with specific specifications and functions to meet customer requirements.

Technological Innovation:

We continuously invest in research and development, adopting the latest technologies and innovative designs to improve the efficiency and performance of our products.

Comprehensive After-Sales Support:

We provide full after-sales services, including installation guidance, operation training, and troubleshooting to ensure customers can use the reactor smoothly.

Global Network:

We have a widespread global distribution network, enabling us to respond quickly to the needs of customers in various regions.

Safety and Compliance:

Our products comply with international safety and environmental standards to ensure user safety during operation.

FAQ

Q: What are the key features of the FCF high pressure chemical reactor?

A: The FCF high pressure chemical reactor features a static sealing structure, where the stirrer is connected to the motor via a magnetic coupler, transferring torque without contact. This eliminates the need for dynamic seals, completely resolving the leakage problem that occurs with traditional stirring methods.

Q: What are the pressure and temperature ranges for the FCF high pressure chemical reactor?

A: The working pressure of the FCF high pressure chemical reactor can reach up to 22 MPa, and the design temperature can reach up to 350°C.

Q: What materials are used in the construction of the FCF high pressure chemical reactor?

A: The FCF high pressure chemical reactor is typically made from stainless steel, including 304 stainless steel and 316 stainless steel, which offer excellent corrosion resistance and mechanical strength.

Q: How is temperature controlled in the FCF high pressure chemical reactor?

A: The FCF high pressure chemical reactor uses temperature sensors (such as RTD or thermocouples) to monitor the temperature inside the reactor in real-time. The temperature signal is transmitted to the control system, which uses PID control or other advanced control algorithms to adjust the flow rate of heating or cooling media, maintaining the temperature within the desired range.

Product Parameters

Model | Capacity (L) | Setting Pressure (MPa) | Setting Temperature (℃) | Heating Power (kW) | Stirring Torque (N. cm) | Voltage (V/Hz) |

FCF-0.1 | 0.1 | 22 | 350 | 0.6 | 120 | 220 50/60 |

FCF-1 | 1 | 22 | 350 | 1.5 | 120 | 220 50/60 |

FCF-5 | 5 | 22 | 350 | 4 | 120 | 220 50/60 |

FCF-20 | 20 | 22 | 350 | 10 | 120 | 220 50/60 |

FCF-50 | 50 | 10 | 350 | 12 | 120 | 220 50/60 |

FCF-100 | 100 | 60 | 350 | 14 | 120 | 220 50/60 |

Model | Capacity (L) | Setting Pressure (MPa) | Setting Temperature (℃) |

FCF-0.1 | 0.1 | 22 | 350 |

FCF-1 | 1 | 22 | 350 |

FCF-5 | 5 | 22 | 350 |

FCF-20 | 20 | 22 | 350 |

FCF-50 | 50 | 10 | 350 |

FCF-100 | 100 | 60 | 350 |

Contact Us Now

WhatsApp:

Email:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China