Product Overview

The 100L jacketed glass reactor is a large-scale laboratory device with an effective volume of 100 liters, suitable for large-scale chemical reactions and material processing. Its double-layer glass design allows the inner layer to hold reaction solvents for stirring reactions, while the outer jacket can circulate heating or cooling media (such as refrigerants, hot water, or thermal oil) for temperature control. Under a sealed environment, the reactor can perform stirring reactions at constant temperatures under atmospheric or vacuum conditions and supports reflux and distillation of reaction solutions.

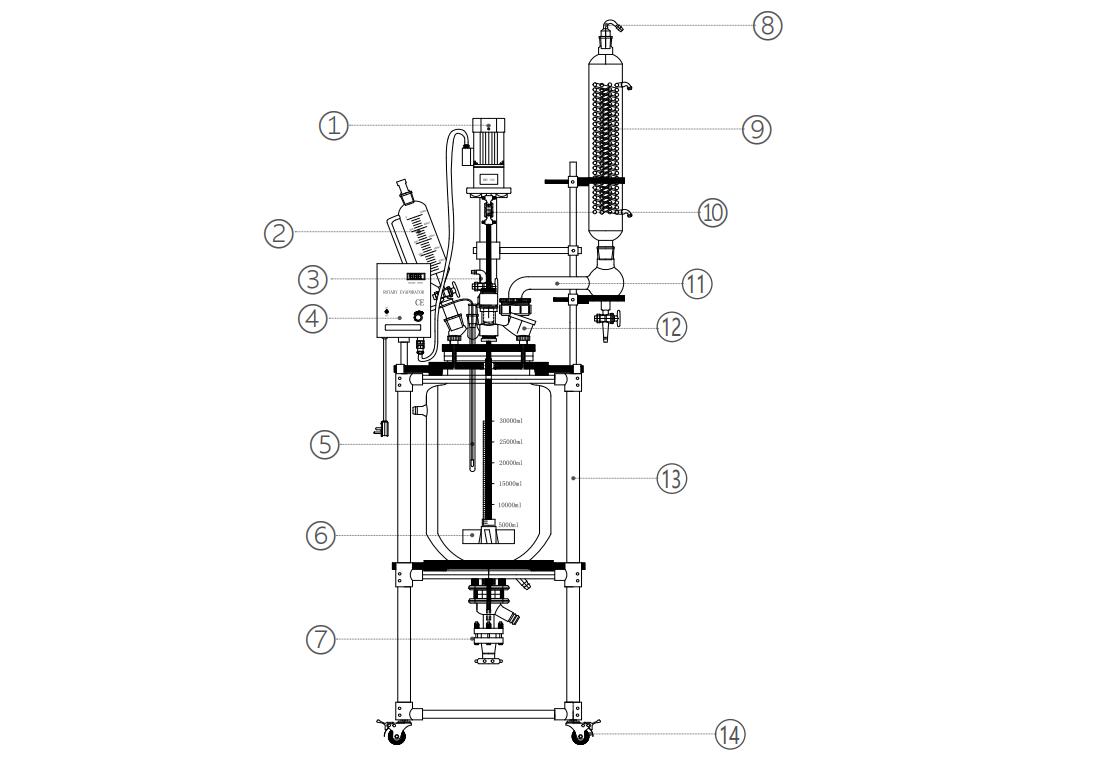

Component Structure

Part | Part | ||

1 | Motor | 8 | Air Extraction Head |

2 | Constant Pressure Funnel | 9 | Condenser |

3 | Release Valve | 10 | Universal Joint |

4 | Speed control Box | 11 | Return Elbow |

5 | Thermowell | 12 | Solid Feed Port |

6 | PTFE Stirring Blades | 13 | 304 Stainless Steel Frame |

7 | Discharge Valve | 14 | Brake Casters |

Product Features

Large Capacity Design: With an effective volume of 100 liters, the 100L glass reactor is ideal for large-scale chemical reactions and material handling.

Temperature Control: Capable of operating over a wide temperature range (typically from -120°C to 200°C), it meets the needs of processes requiring both low and high temperatures.

Pressure Resistance: The 100L jacketed glass reactor can operate under atmospheric and vacuum conditions, with some pressure tolerance, making it suitable for reactions requiring pressure control.

High Transparency Glass: Constructed from borosilicate glass, it provides high transparency for easy monitoring of the reaction process.

Corrosion Resistance: The glass material offers excellent chemical corrosion resistance, suitable for various chemical media.

Safety Sealing: High-quality sealing materials ensure reliable sealing performance under high temperatures, high pressure, or vacuum conditions.

Applications

Chemical Synthesis:

The 100L jacketed glass reactor provides a controlled environment for synthesizing various chemicals in the pharmaceutical and chemical industries, enabling precise monitoring and adjustment of reactions.Polymerization Reactions:

The reactor is suitable for polymerization processes of materials such as resins, adhesives, and plastics. Controlled conditions, including temperature and pressure, are critical for achieving desired polymer properties.Distillation Processes:

Equipped with distillation functionality, the 100L glass reactor can separate solvents and recover valuable chemicals by evaporating and condensing different substances.Extraction Processes:

The 100L jacketed glass reactor is widely used for extracting plant materials, isolating natural products, and purifying chemicals. Its inert glass material ensures that the extraction process remains unaffected by chemical reactions with the reactor’s construction materials.Biotechnology and Vaccine Production:

In the field of biotechnology, this reactor plays a critical role in producing biological pharmaceuticals, such as monoclonal antibodies and recombinant proteins. It is also used in vaccine production, including the cultivation of viral vectors and recombinant organisms.Food Industry:

The 100L glass reactor is also applicable in areas such as food additive production and ingredient extraction. As the food industry continues to upgrade its technology, the reactor shows promising market potential.

Precautions

Operator Training: Operators must undergo professional training to understand the equipment's structure, performance, and operating procedures for safe and efficient use.

Seal Inspection: Before each use, check the reactor’s seals for wear or aging to ensure there are no leaks during the chemical reaction process.

Cleaning and Maintenance: Clean the reactor promptly after use to prevent residue from corroding the equipment or affecting subsequent experiments.

Temperature Control: Strictly follow experimental requirements when setting temperatures to avoid exceeding limits, which could damage the glass vessel or affect experimental results.

Electrical Safety: Ensure all electrical connections are secure and reliable to avoid electrical faults or short circuits.

Regular Maintenance: Periodically inspect and maintain the reactor, including the motor, seals, jacket, and stirrer, replacing worn components promptly.

Adherence to Operating Procedures: Always operate the reactor according to the manual, avoiding unauthorized changes to operating conditions or overloading the equipment.

Emergency Handling: Be familiar with emergency stop procedures and contingency measures to quickly respond to abnormalities.

FAQ

Q: What is the function of the jacket in the 100L jacketed glass reactor?

A: The jacket is designed to control the reactor’s internal temperature by circulating cooling or heating media (such as water or oil). This allows precise temperature regulation to meet the requirements of various chemical and physical processes.

Q: What are the heating methods for the 100L glass reactor?

A: The 100L jacketed glass reactor can be heated using electric heaters, steam, or hot water. The choice of method depends on laboratory conditions and specific reaction requirements.

Q: Can the stirring speed of the 100L jacketed glass reactor be adjusted?

A: Yes, the 100L glass reactor is typically equipped with a motor that supports variable frequency speed control, allowing the stirring speed to be adjusted according to the reaction’s requirements.

Q: What is the temperature range of the 100L jacketed glass reactor?

A: The working temperature range for this reactor is from -120°C to 200°C (depending on the parameters of the selected auxiliary equipment).

Product Parameters

Model | Power(W ) | Stirring Speed(rmp) | Diameter | Capacity(L) | Power Supply | Motor Torque(g/cm) |

S-1L | 60 | 0~600(Max.1300) | 12 | 1 | 220V 50/60 Hz | 2000 |

S-2L | 60 | 0~600(Max.1300) | 12 | 2 | 220V 50/60 Hz | 2400 |

S-3L | 60 | 0~600(Max.1300) | 12 | 3 | 220V 50/60 Hz | 2400 |

S-5L | 60 | 0~600(Max.1300) | 12 | 5 | 220V 50/60 Hz | 4800 |

S-10L | 120 | 0~600(Max.1300) | 12 | 10 | 220V 50/60 Hz | 1000 |

S-20L | 120 | 0~600(Max.1300) | 12 | 20 | 220V 50/60 Hz | 1200 |

S-30L | 120 | 0~600(Max.1300) | 12 | 30 | 220V 50/60 Hz | 1200 |

S-50L | 120 | 0~600(Max.1300) | 12 | 50 | 220V 50/60 Hz | 1500 |

S-100L | 250 | 0~600(Max.1300) | 15 | 100 | 220V 50/60 Hz | 3000 |

Model | Power(W ) | Stirring Speed(rmp) | Diameter |

S-1L | 60 | 0~600(Max.1300) | 12 |

S-2L | 60 | 0~600(Max.1300) | 12 |

S-3L | 60 | 0~600(Max.1300) | 12 |

S-5L | 60 | 0~600(Max.1300) | 12 |

S-10L | 120 | 0~600(Max.1300) | 12 |

S-20L | 120 | 0~600(Max.1300) | 12 |

S-30L | 120 | 0~600(Max.1300) | 12 |

S-50L | 120 | 0~600(Max.1300) | 12 |

S-100L | 250 | 0~600(Max.1300) | 15 |

Contact Us Now

WhatsApp:

Email:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China