Product Overview

The 1L glass reactor is known for its compact 1-liter capacity and dual-layer jacket design, which allows for precise temperature control. The jacket circulates hot or cold media to heat or cool the reaction medium, ensuring stability and safety during experiments. The 1L jacketed glass reactor is particularly suitable for small-scale chemical synthesis and pharmaceutical processes, offering high transparency and excellent chemical stability. It is an ideal choice for laboratory and pilot-scale production.

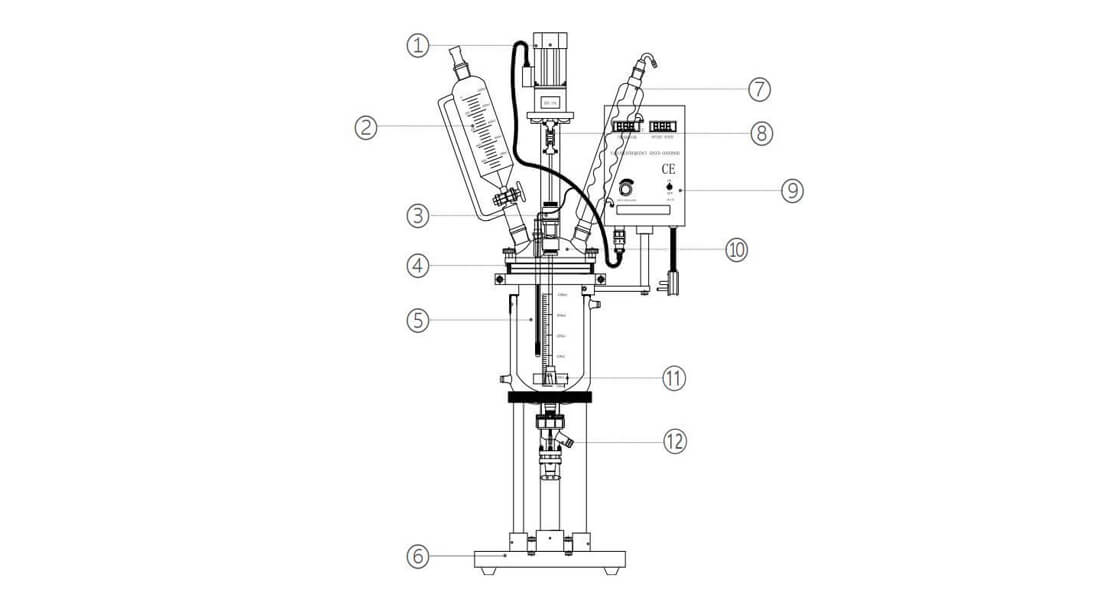

Component Structure

Part | Part | ||

1 | Motor | 7 | Condenser |

2 | Constant Pressure Funnel | 8 | Universal Joint |

3 | Mechanical Sealing | 9 | Speed Control Box |

4 | Flange | 10 | Kettle Cover |

5 | Kettle Body | 11 | Ptfe Stirring Blades |

6 | 304 Bottom Plate | 12 | Discharge Valve |

Product Features

The design of the 1L glass reactor and 1L jacketed glass reactor emphasizes the portability and precise control of small-capacity reactors. Their main features include:

Dual-layer Glass Design: The 1L glass reactor and 1L jacketed glass reactor both feature a dual-layer glass structure. The inner layer is used for placing the reaction solvent for stirring, while the jacket layer circulates various hot or cold media (such as coolant, hot water, or hot oil) to heat or cool the reaction.

Precise Temperature Control: By circulating hot or cold media within the jacket, the 1L jacketed glass reactor can maintain a constant temperature for stirring reactions under both normal and vacuum conditions. It can also support reflux and distillation of reaction solutions, making it ideal for fine chemicals, biopharmaceuticals, and new material synthesis.

High Borosilicate Glass Material: Both the 1L glass reactor and 1L jacketed glass reactor are made from GG17 high borosilicate glass, which provides excellent chemical and physical properties.

Variable Speed Motor: Both reactors are equipped with a variable-speed, AC induction motor, providing stable and constant speed without brushes or sparks, ensuring safe and continuous operation.

Versatility: The 1L glass reactor can function at ambient temperatures, and by circulating tap water, it can quickly dissipate heat, making it suitable for reactions under various temperature conditions. The 1L jacketed glass reactor offers similar versatility and ensures more efficient temperature control.

Application Scenarios

Both the 1L glass reactor and 1L jacketed glass reactor are widely used in laboratory small-scale experiments and educational demonstrations. They are ideal for industries such as chemicals, food, pharmaceuticals, agrochemicals, active pharmaceutical ingredients (APIs), dyes, and aromatic compounds, particularly in production processes that require precise temperature control.

Chemical Synthesis: In chemical synthesis, both the 1L glass reactor and 1L jacketed glass reactor can be used for synthesizing complex organic molecules such as drugs and dyes. Real-time observation of the reaction process allows for timely adjustments to reaction conditions, improving product purity and yield.

Material Research and Development: In the synthesis of nanomaterials and functional materials, both reactors play a vital role. By providing high-pressure and high-temperature environments, they accelerate material synthesis rates and help achieve the desired performance of new materials.

Pharmaceutical Industry: Many key steps in the pharmaceutical industry require the use of reactors. From the synthesis of active pharmaceutical ingredients (APIs) to the preparation of intermediates and the formation of final products, both the 1L glass reactor and 1L jacketed glass reactor are indispensable. They are also used in biopharmaceutical processes, such as antibiotic fermentation.

Food Industry: Both reactors are widely used in the food industry for various processing tasks. For example, in dairy production, they are used for heating and mixing raw materials. They also play an important role in the preparation of seasonings and additives.

Maintenance and Care

Here are some maintenance and care guidelines for the 1L glass reactor and 1L jacketed glass reactor:

Cleaning: Before and after use, the reactor must be cleaned to prevent contamination that could affect experimental results. Use a neutral detergent and rinse thoroughly with clean water.

Prevent Impact: As glass is fragile, handle both the 1L glass reactor and the 1L jacketed glass reactor with care to avoid impacts and collisions, which may lead to breakage.

Regular Inspection: Perform regular checks of the reactors’ sealing and the integrity of the jackets to ensure safety and efficiency.

Personal Protection: Operators should wear appropriate personal protective equipment, such as lab gloves and safety goggles, to minimize the risk of injury from chemicals, heat, or radiation.

FAQ

Q: What should I do if the heat transfer is poor, and heating or cooling is slow?

A: Use heat transfer media with better thermal properties; increase the heat transfer area, such as using a jacketed reactor; and increase the temperature differential for better heat transfer.

Q: How should I handle scaling on the inner wall of the 1L glass reactor?

A: Avoid using reactants and products that easily form insoluble substances during the experiment. Regularly clean the inner walls of the reactor using specialized cleaning agents and methods.

Q: What should I do if the speed display does not match the actual speed?

A: First, check if the power supply voltage is stable. A small discrepancy is normal, but if the error is too large, it is recommended to contact our company for further inspection and resolution.

Product Parameters

Model | Power(W ) | Stirring Speed(rmp) | Diameter | Capacity(L) | Power Supply | Motor Torque(g/cm) |

S-1L | 60 | 0~600(Max.1300) | 12 | 1 | 220V 50/60 Hz | 2000 |

S-2L | 60 | 0~600(Max.1300) | 12 | 2 | 220V 50/60 Hz | 2400 |

S-3L | 60 | 0~600(Max.1300) | 12 | 3 | 220V 50/60 Hz | 2400 |

S-5L | 60 | 0~600(Max.1300) | 12 | 5 | 220V 50/60 Hz | 4800 |

S-10L | 120 | 0~600(Max.1300) | 12 | 10 | 220V 50/60 Hz | 1000 |

S-20L | 120 | 0~600(Max.1300) | 12 | 20 | 220V 50/60 Hz | 1200 |

S-30L | 120 | 0~600(Max.1300) | 12 | 30 | 220V 50/60 Hz | 1200 |

S-50L | 120 | 0~600(Max.1300) | 12 | 50 | 220V 50/60 Hz | 1500 |

S-100L | 250 | 0~600(Max.1300) | 15 | 100 | 220V 50/60 Hz | 3000 |

Model | Power(W ) | Stirring Speed(rmp) | Diameter |

S-1L | 60 | 0~600(Max.1300) | 12 |

S-2L | 60 | 0~600(Max.1300) | 12 |

S-3L | 60 | 0~600(Max.1300) | 12 |

S-5L | 60 | 0~600(Max.1300) | 12 |

S-10L | 120 | 0~600(Max.1300) | 12 |

S-20L | 120 | 0~600(Max.1300) | 12 |

S-30L | 120 | 0~600(Max.1300) | 12 |

S-50L | 120 | 0~600(Max.1300) | 12 |

S-100L | 250 | 0~600(Max.1300) | 15 |

Contact Us Now

WhatsApp:

Email:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China