Product Overview

The 50L jacketed glass reactor vessel is a large-scale laboratory device primarily used for experiments and production in the pharmaceutical, chemical, and biotechnology industries. This reactor operates under vacuum or negative pressure conditions, using constant-speed stirring to uniformly mix raw materials, ensuring thorough reactions within the reactor vessel. All parts in contact with materials are made of high-temperature-resistant and corrosion-resistant borosilicate glass and polytetrafluoroethylene (PTFE), making it especially suitable for reactions involving biologically sensitive substances prone to decomposition or denaturation. It minimizes chemical reactions with various materials.

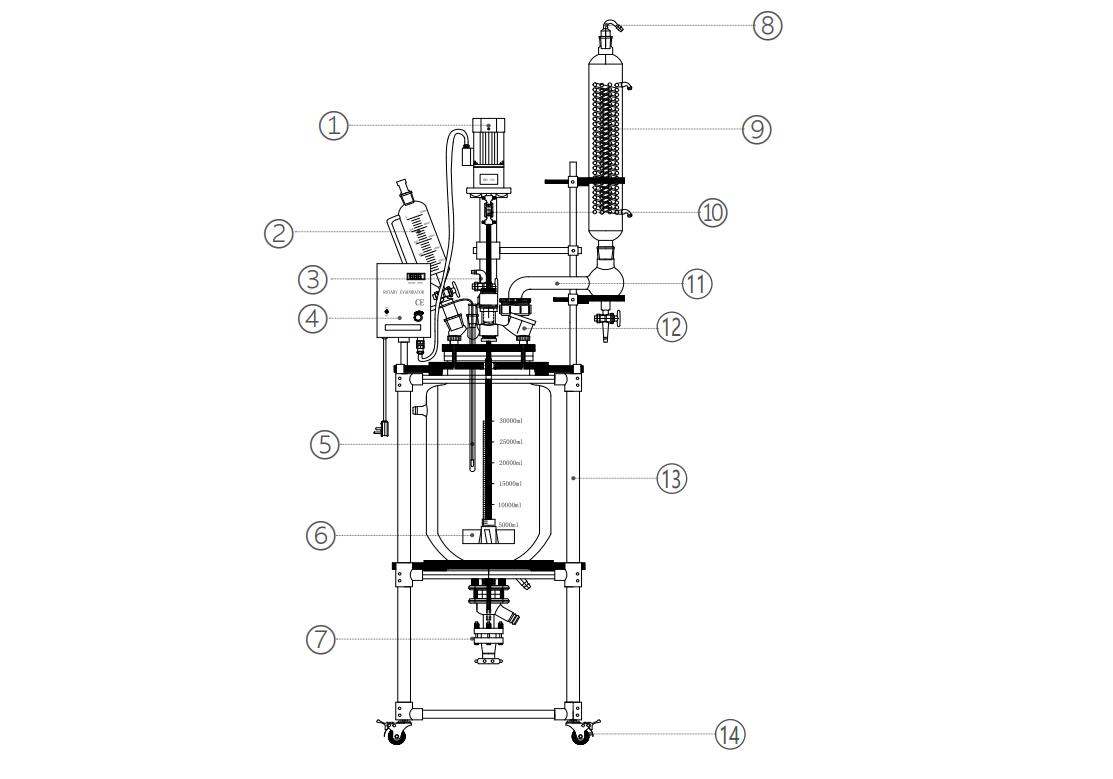

Component Structure

Part | Part | ||

1 | Motor | 8 | Air Extraction Head |

2 | Constant Pressure Funnel | 9 | Condenser |

3 | Release Valve | 10 | Universal Joint |

4 | Speed control Box | 11 | Return Elbow |

5 | Thermowell | 12 | Solid Feed Port |

6 | PTFE Stirring Blades | 13 | 304 Stainless Steel Frame |

7 | Discharge Valve | 14 | Brake Casters |

Product Features

Moderate Capacity: The 50L glass reactor has a capacity suitable for medium- to large-scale chemical reactions and experiments.

Transparent Material: Made of high borosilicate glass, it offers excellent transparency for easy observation of the reaction process.

Jacketed Design: The jacket structure allows heating or cooling with flexible temperature control.

Stirring System: Equipped with an efficient stirring mechanism to ensure uniform mixing of materials.

Sealing Performance: Features excellent sealing design to prevent material leakage.

Applications

Chemical Synthesis:

The 50L jacketed glass reactor plays a crucial role in the synthesis of various chemicals in industries such as chemical, pharmaceutical, and biotechnology. It provides a controlled environment for precise monitoring and adjustment of reactions.Polymerization Reactions:

This reactor is suitable for polymerization of materials like resins, adhesives, and plastics. Controlled conditions, including temperature and pressure, are essential for achieving desired polymer properties.Distillation:

A 50L jacketed glass reactor equipped with distillation functionality can separate solvents and recover valuable chemicals. The distillation process involves heating the mixture to evaporate components, which are then condensed back into liquid form, enabling separation based on boiling points.Extraction:

The 50L glass reactor is suitable for extracting plant materials, separating natural products, and purifying chemicals. The inertness of the glass ensures that the extraction process is free from any chemical reactions with the reactor materials.High- and Low-Temperature Reactions:

The 50L jacketed glass reactor can handle high-temperature reactions (up to 200°C) and low-temperature reactions (down to -120°C), making it versatile for a wide range of temperature requirements.

Working Principle

The 50L jacketed glass reactor operates on its double-layered structure. The inner layer holds the reaction materials, while the outer jacket facilitates temperature control by circulating heating or cooling media (e.g., hot water, cold water, or antifreeze). The circulating fluid in the jacket ensures uniform heating or cooling of the reactor contents, meeting the temperature requirements for various chemical reactions. Additionally, the internal stirrer maintains a constant speed, ensuring uniform mixing of materials to promote the reaction.

Maintenance and Care

Cleaning the Reactor: Clean the 50L glass reactor before and after use to prevent cross-contamination and equipment malfunction.

Inspecting Sealing Performance: Regularly check and adjust the reactor’s sealing to prevent liquid leaks and ensure safety during operation.

Checking Discharge Valve and External Bath: Inspect the discharge valve and external bath for leaks, ensuring no leakage occurs.

Storage: Store the glass reactor in a safe, dry location free from physical pressure or contamination to maintain its integrity between uses.

Electrical Components: Ensure the electrical components are kept dry and protected from water or moisture.

Lubricating Joints: Periodically loosen the joints, apply vacuum grease to glass interfaces, and retighten to avoid joint seizing.

Maintaining Cleanliness: After use, wipe down the machine’s surface with a soft cloth to remove oil, stains, and solvents.

FAQ

Q: What is the material of the 50L jacketed glass reactor?

A: The 50L jacketed glass reactor is typically made of borosilicate glass (GG17 borosilicate glass), known for its excellent acid and alkali resistance and thermal shock resistance, making it suitable for a variety of chemical and biological reactions.

Q: What is the purpose of the jacket in the jacketed glass reactor?

A: The jacket in the 50L glass reactor is primarily used to control the internal temperature of the reactor by circulating cooling or heating media (such as water, oil, or special media). This enables precise temperature control to meet the requirements of various chemical reactions.

Q: What is the operating temperature range of the 50L jacketed glass reactor?

A: The maximum operating temperature of the 50L jacketed glass reactor can reach approximately 200°C, while the minimum temperature can go as low as -120°C. The specific range depends on the parameters of the selected auxiliary equipment.

Q: How should the 50L glass reactor be cleaned and maintained?

A: For cleaning, use a mild detergent and soft brushes, avoiding hard brushes or abrasive cleaners to prevent scratching the glass surface. For maintenance, regularly check the condition of seals and gaskets, replacing them as needed to ensure proper sealing and extend the reactor’s service life.

Q: What are the safety precautions when operating a 50L jacketed glass reactor?

A: During operation, ensure all safety devices (such as pressure gauges and thermometers) are functioning properly to avoid overpressure and overheating. Ensure good sealing to prevent leaks. During heating or cooling, proceed gradually to avoid glass breakage due to rapid temperature changes. Operators should wear appropriate protective gear and follow professional guidance during operation.

Product Parameters

Model | Power(W ) | Stirring Speed(rmp) | Diameter | Capacity(L) | Power Supply | Motor Torque(g/cm) |

S-1L | 60 | 0~600(Max.1300) | 12 | 1 | 220V 50/60 Hz | 2000 |

S-2L | 60 | 0~600(Max.1300) | 12 | 2 | 220V 50/60 Hz | 2400 |

S-3L | 60 | 0~600(Max.1300) | 12 | 3 | 220V 50/60 Hz | 2400 |

S-5L | 60 | 0~600(Max.1300) | 12 | 5 | 220V 50/60 Hz | 4800 |

S-10L | 120 | 0~600(Max.1300) | 12 | 10 | 220V 50/60 Hz | 1000 |

S-20L | 120 | 0~600(Max.1300) | 12 | 20 | 220V 50/60 Hz | 1200 |

S-30L | 120 | 0~600(Max.1300) | 12 | 30 | 220V 50/60 Hz | 1200 |

S-50L | 120 | 0~600(Max.1300) | 12 | 50 | 220V 50/60 Hz | 1500 |

S-100L | 250 | 0~600(Max.1300) | 15 | 100 | 220V 50/60 Hz | 3000 |

Model | Power(W ) | Stirring Speed(rmp) | Diameter |

S-1L | 60 | 0~600(Max.1300) | 12 |

S-2L | 60 | 0~600(Max.1300) | 12 |

S-3L | 60 | 0~600(Max.1300) | 12 |

S-5L | 60 | 0~600(Max.1300) | 12 |

S-10L | 120 | 0~600(Max.1300) | 12 |

S-20L | 120 | 0~600(Max.1300) | 12 |

S-30L | 120 | 0~600(Max.1300) | 12 |

S-50L | 120 | 0~600(Max.1300) | 12 |

S-100L | 250 | 0~600(Max.1300) | 15 |

Contact Us Now

WhatsApp:

Email:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China