Product Overview

The 20L jacketed glass reactor, made of high borosilicate glass, offers excellent chemical stability and high-temperature resistance. With a working capacity of 20L, its jacket allows precise temperature control by circulating heating or cooling media. It is suitable for various chemical reactions and biopharmaceutical processes. Its high transparency facilitates observation, while its reasonable structure ensures ease of maintenance, making it an ideal pilot and production device for laboratories and industrial production.

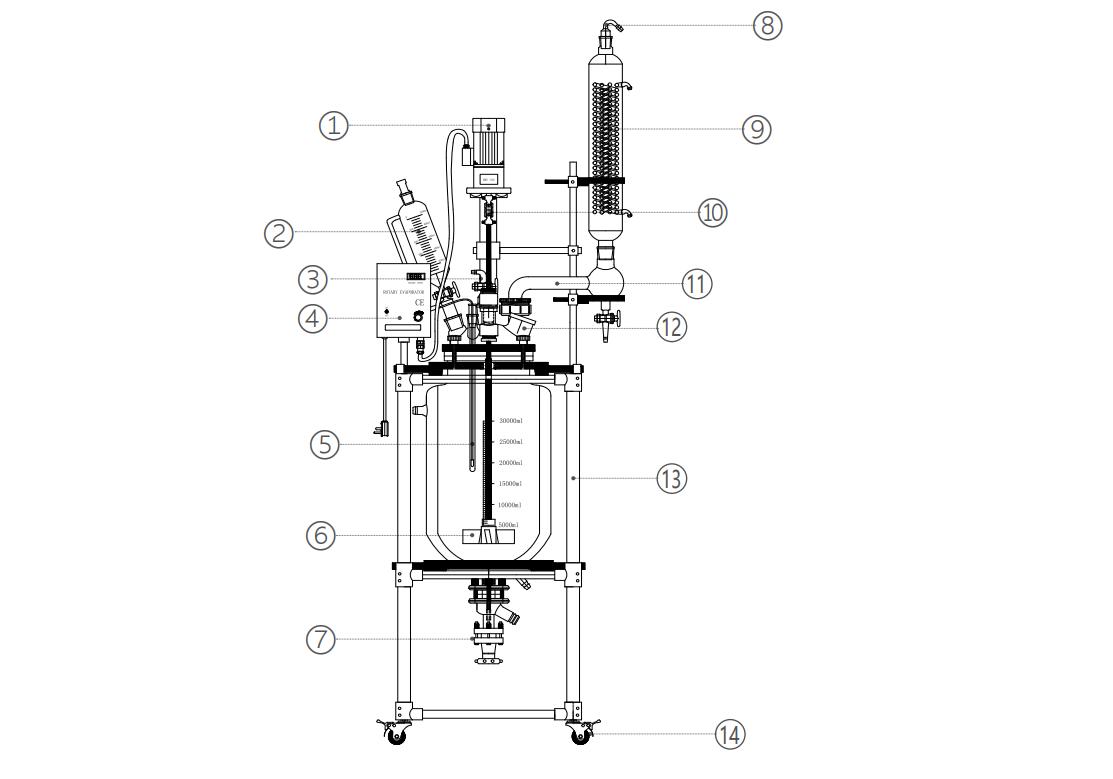

Component Structure

Part | Part | ||

1 | Motor | 8 | Air Extraction Head |

2 | Constant Pressure Funnel | 9 | Condenser |

3 | Release Valve | 10 | Universal Joint |

4 | Speed control Box | 11 | Return Elbow |

5 | Thermowell | 12 | Solid Feed Port |

6 | PTFE Stirring Blades | 13 | 304 Stainless Steel Frame |

7 | Discharge Valve | 14 | Brake Casters |

Product Features

High Borosilicate Glass Material: The body of the 20L glass reactor is made of high borosilicate glass, which is corrosion-resistant, heat-resistant, and highly transparent, enabling clear observation of the reaction process.

Temperature Control: The jacket design allows circulating fluids such as water or oil to heat or cool the reactor contents, achieving precise temperature control.

Versatility: With different configurations, the 20L jacketed glass reactor can precisely control heating, evaporation, cooling, and mixing (ranging from low to high speeds). It is suitable for various applications, such as new material synthesis, homogeneous reactions, extraction, and purification.

Variable Frequency Motor: Equipped with a variable frequency motor with digital display and AC induction technology, it operates without brushes or sparks, ensuring safety and noise-free performance.

Multi-functional Lid: The reactor lid has six ports to accommodate diverse process requirements such as addition, reflux, and temperature measurement. The lid is easy to disassemble and clean.

Applications

Chemical Industry:

The 20L jacketed glass reactor is widely used in chemical synthesis and catalyst evaluation due to its excellent corrosion resistance and transparency. Its jacket design enables precise heating or cooling of reaction materials to meet specific temperature requirements for different chemical reactions.Pharmaceutical Industry:

In drug research and production, the 20L glass reactor is ideal for synthesizing active pharmaceutical ingredients and intermediates. Its transparent material allows researchers to observe reaction progress and adjust experimental conditions in real time.New Material Research and Development:

The 20L jacketed glass reactor provides a stable environment for synthesizing and modifying new materials. Its precise temperature control optimizes material performance, increasing research efficiency.Teaching and Research:

In universities and research institutions, the 20L glass reactor is used for studying chemical reaction mechanisms and testing catalyst performance. It helps cultivate students' practical skills and improves research quality.Other Fields:

Additionally, the 20L jacketed glass reactor is suitable for related processes in industries such as food, dyes, and pesticides. Its versatility and adaptability make it widely applicable across various sectors.

Why Choose Us

Superior Quality: Our 20L glass reactors are made of high-quality borosilicate glass, offering excellent corrosion resistance and heat resistance to ensure accuracy and reliability in experimental results.

Technological Innovation: We continuously invest in R&D to optimize product structures and enhance equipment performance. The jacket design enables fast and uniform heating or cooling, meeting diverse experimental needs.

Comprehensive Services: We provide thorough pre-sales consultation, in-sales guidance, and post-sales support to ensure customers receive timely technical assistance and solutions.

Rich Experience: With years of experience in manufacturing glass reactors, we have accumulated extensive industry knowledge and customer case studies, enabling us to offer customized products and services.

By choosing our company, you will receive high-quality products, professional technical support, and worry-free after-sales service, helping your research and production projects achieve greater success.

FAQ

Q: How to choose the appropriate heating method to optimize reaction efficiency?

A: Choosing the right heating method is crucial for optimizing reaction efficiency. For the 20L jacketed glass reactor, common heating methods include electric heating, steam heating, and heat transfer oil heating. When selecting a heating method, consider factors such as the properties of the reaction materials, reaction temperature, heating speed, and energy consumption. For reactions requiring precise temperature control, electric heating is recommended. For large-scale production, steam or heat transfer oil heating might be more cost-effective.

Q: How does the stirring efficiency of the reactor impact experimental results?

A: Stirring efficiency directly affects the uniformity of material mixing and reaction rates. Insufficient stirring efficiency may lead to uneven mixing, negatively impacting reaction outcomes. When selecting a 20L glass reactor, pay attention to the design and performance of its stirring system to ensure it meets experimental requirements. Additionally, regularly inspect the stirrer for wear during use, replacing damaged components promptly to maintain stable stirring efficiency.

Q: How to ensure the long-term stable operation of the 20L jacketed glass reactor?

A: To ensure long-term stable operation, regularly clean and maintain the reactor and consider the following:

Strictly control operating temperature and pressure to avoid exceeding the reactor's design limits.

Use suitable reaction media and catalysts to minimize equipment corrosion and wear.

Periodically inspect the reactor's electrical and control systems to ensure proper functioning.

Establish comprehensive equipment management procedures and operational guidelines to enhance operators' skills and awareness.

Product Parameters

Model | Power(W ) | Stirring Speed(rmp) | Diameter | Capacity(L) | Power Supply | Motor Torque(g/cm) |

S-1L | 60 | 0~600(Max.1300) | 12 | 1 | 220V 50/60 Hz | 2000 |

S-2L | 60 | 0~600(Max.1300) | 12 | 2 | 220V 50/60 Hz | 2400 |

S-3L | 60 | 0~600(Max.1300) | 12 | 3 | 220V 50/60 Hz | 2400 |

S-5L | 60 | 0~600(Max.1300) | 12 | 5 | 220V 50/60 Hz | 4800 |

S-10L | 120 | 0~600(Max.1300) | 12 | 10 | 220V 50/60 Hz | 1000 |

S-20L | 120 | 0~600(Max.1300) | 12 | 20 | 220V 50/60 Hz | 1200 |

S-30L | 120 | 0~600(Max.1300) | 12 | 30 | 220V 50/60 Hz | 1200 |

S-50L | 120 | 0~600(Max.1300) | 12 | 50 | 220V 50/60 Hz | 1500 |

S-100L | 250 | 0~600(Max.1300) | 15 | 100 | 220V 50/60 Hz | 3000 |

Model | Power(W ) | Stirring Speed(rmp) | Diameter |

S-1L | 60 | 0~600(Max.1300) | 12 |

S-2L | 60 | 0~600(Max.1300) | 12 |

S-3L | 60 | 0~600(Max.1300) | 12 |

S-5L | 60 | 0~600(Max.1300) | 12 |

S-10L | 120 | 0~600(Max.1300) | 12 |

S-20L | 120 | 0~600(Max.1300) | 12 |

S-30L | 120 | 0~600(Max.1300) | 12 |

S-50L | 120 | 0~600(Max.1300) | 12 |

S-100L | 250 | 0~600(Max.1300) | 15 |

Contact Us Now

WhatsApp:

Email:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China