Product Overview

The TGYF high pressure lab reactor is a desktop high-pressure reaction vessel, available in various volume specifications ranging from 50ml to 500ml, making it ideal for laboratory and small-scale experiments. It is designed to withstand pressures up to 22 MPa and temperatures up to 350°C, making it suitable for reactions involving flammable, explosive, and highly permeable chemical media. Due to its compact structure, ease of operation, and reliable safety features, the TGYF high pressure lab reactor has become the preferred reaction vessel for processes in industries such as petroleum, chemicals, organic synthesis, and food processing, especially for reactions like sulfurization and oxidation.

Product Features

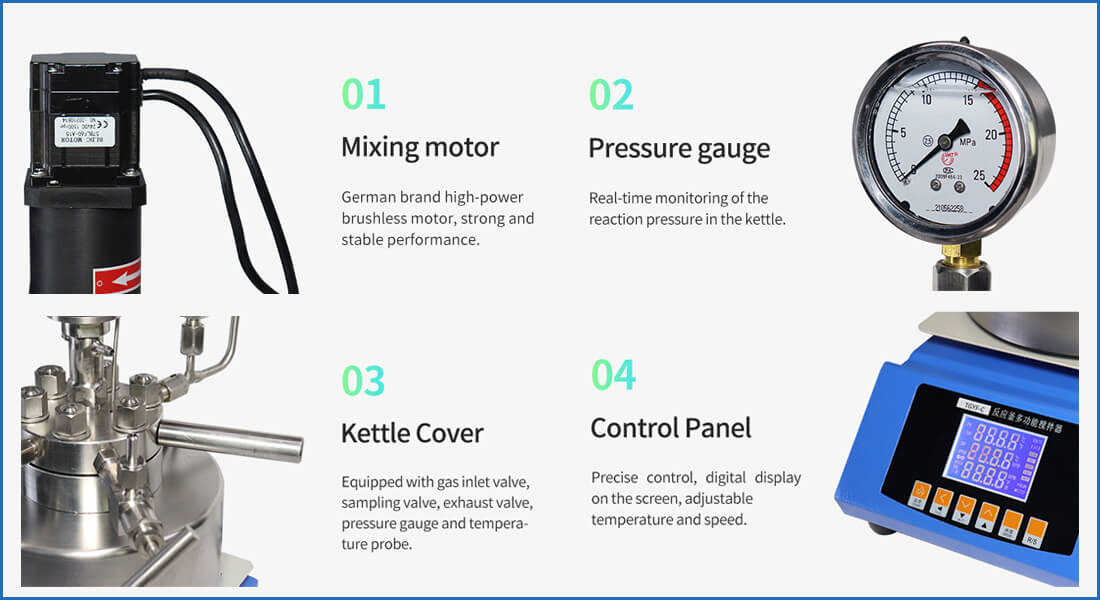

Magnetic Stirring:

The TGYF high pressure lab reactor uses an internal magnetic stirring system, eliminating the risk of seal leakage, ensuring a leak-proof operation, and making the experiment safer.

High-Quality Motor:

The stirring motor is a high-power, brushless motor imported from Germany, providing stable and powerful performance.

Convenient Operation:

Equipped with a gas inlet needle valve, sampling valve, and exhaust valve, the reactor allows for easy sampling, reaction progress analysis, vacuum treatment, and gas replacement before reactions.

Rapid Heating:

The heating unit uses a modular electric heating system, which provides fast heating and precise control, with digital temperature display.

Compact Structure:

The reactor has a small and simple structure, making it reliable and easy to use in laboratories and for small-scale experiments.

Stepless Speed Adjustment:

The stirring speed is adjustable with stepless speed control, providing smooth low-speed operation and powerful high-speed stirring.

Intelligent Temperature Control:

Temperature control is achieved through an encoder switch, with digital display, including timing and self-calibration features, offering high measurement accuracy and minimal temperature fluctuation.

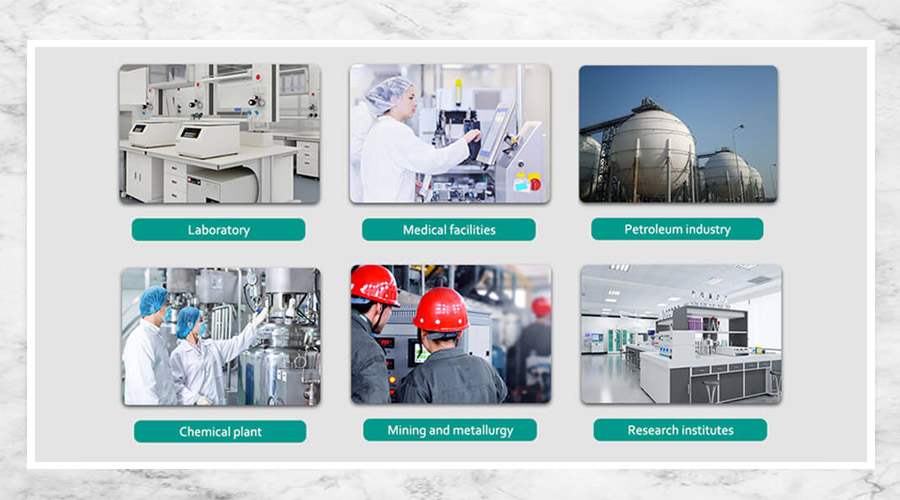

Application Areas

Chemical Synthesis:

Suitable for various chemical reactions, such as high-pressure hydrogenation, polymerization, and catalytic reactions, which can be performed under controlled high-temperature and high-pressure conditions.

Material Development:

Used for the synthesis and modification of new materials, including the preparation of polymer materials and nanomaterials.

Pharmaceutical Development:

Ideal for drug synthesis and reaction optimization, particularly for the synthesis of complex organic compounds.

Educational and Laboratory Research:

Widely used in educational institutions and laboratories for a wide range of chemical reaction experiments and research.

Chemicals and Fine Chemicals:

Applied in the chemical, fine chemicals, biopharmaceuticals, and new material synthesis industries.

Biopharmaceuticals:

In the biopharmaceutical industry, the TGYF high pressure lab reactor can be used for high-pressure reactions during drug synthesis processes.

New Material Synthesis:

Suitable for the synthesis of new energy materials, such as high-pressure deposition for thin film processing.

Working Principle

The TGYF high pressure lab reactor works by performing chemical reactions inside a sealed stainless steel container. External electric heating modules supply the necessary heat, while the built-in magnetic stirrer ensures uniform mixing of materials without any direct contact. This design avoids the potential leakage issues that may arise from traditional mechanical seals, ensuring safe operation under high-temperature and high-pressure conditions. The high-pressure environment accelerates reaction rates, enhances solubility, and promotes specific chemical reactions. Safety valves, pressure gauges, and other devices are integrated to ensure pressure control, preventing excessive pressure buildup.

Precautions

Gas Filling and Venting Speed:

The filling and venting process should be performed slowly to prevent solvent spillage.

Gradual Heating:

When using the high pressure lab reactor for heating reactions, heat should be applied gradually. Do not expose the reactor to high temperatures directly to avoid excessive pressure buildup.

Pre-Use Inspection:

Prior to use, a heating and pressurization leak test should be performed. The test medium can be air or nitrogen, but inert gases are preferred. Oxygen or other flammable/explosive gases should never be used.

Cleaning Operations:

Ensure that the reactor is clean and free from impurities or residues before heating, as contaminants can lead to explosions or gas leakage.

Cleaning and Maintenance:

After the experiment, clean the reactor to remove any residual materials. Perform regular maintenance and checks to ensure long-term stable operation.

Safety Protection:

Operators should wear necessary safety gear such as goggles, gloves, and protective clothing to prevent chemical splashes or burns from high temperatures.

Understand Material Properties:

Before conducting high-pressure experiments, operators must thoroughly understand the properties of the materials being used, including their reactivity, volatility, and toxicity, to assess potential risks.

Follow Operating Procedures:

Strictly adhere to operating instructions and never alter reaction conditions (e.g., temperature or pressure) without proper authorization, to avoid equipment damage or personal injury.

Regular Training:

Personnel operating the equipment should undergo regular training to familiarize themselves with the reactor's structure, working principles, and safety procedures, improving their safety awareness and operational skills.

After-Sales Service

Warranty Service:

The TGYF high pressure lab reactor comes with a standard warranty that covers equipment failures caused by manufacturing defects, ensuring users' rights during the product's service life.

Technical Support:

Online and phone technical support is available to assist users with any technical questions or issues encountered during operation, ensuring smooth and effective use of the reactor.

Operational Training:

We provide operational training for users, including initial usage guidance, operational procedures, and safety precautions, to help users quickly master reactor operation skills.

Regular Maintenance Services:

Regular inspections and maintenance services are provided, including performance checks, cleaning, and calibration, to ensure long-term stable operation of the reactor.

Parts and Consumables Supply:

Timely supply of original parts and consumables to ensure the normal operation of the equipment and avoid downtime due to shortages.

Fault Diagnosis and Repair:

We offer fault diagnosis services to help users quickly identify and resolve operational issues, minimizing the impact of equipment failures on the user's work.

FAQ

Q: What is unique about the stirring method in the TGYF high pressure lab reactor?

A: The TGYF high pressure lab reactor uses magnetic stirring, eliminating the need for shaft seals and associated maintenance issues, ensuring a leak-proof, safe operation without exposed rotating parts.

Q: How is heating provided in the TGYF high pressure lab reactor?

A: The TGYF high pressure lab reactor uses a modular electric heating system, which provides fast heating, precise control, and a digital temperature display.

Q: What is the design pressure and temperature for the TGYF high pressure lab reactor?

A: The design pressure of the TGYF high pressure lab reactor is 22 MPa, and the design temperature is 350°C.

Q: What is the stirring speed range of the TGYF high pressure lab reactor?

A: The stirring speed of the TGYF high pressure lab reactor ranges from 0 to 2000 rpm (depending on the specific model).

Q: What is the filling capacity requirement for the TGYF high pressure lab reactor?

A: The filling capacity inside the TGYF high pressure lab reactor should not exceed 80%.

Product Parameters

Model | TGYF-C | ||||

Volume(L) | 0.05 | 0.1 | 0.25 | 0.5 | 1 |

Pressure | 22MPa | ||||

Temperature | 350℃ | ||||

Stirring speed | 1800 r/min | ||||

Heating power | 0.7kW | 0.7kW | 0.7kW | 1.5kW | 1.5kW |

Heating mode | Modular electrical heating | ||||

Stirring method | Mechanical stirring | ||||

Material | Stainless steel 304, 316 | ||||

Model | TGYF-C | ||||

Volume(L) | 0.05 | 0.1 | 0.25 | 0.5 | 1 |

Pressure | 22MPa | ||||

Temperature | 350℃ | ||||

Stirring speed | 1800 r/min | ||||

Heating power | 0.7kW | 0.7kW | 0.7kW | 1.5kW | 1.5kW |

Heating mode | Modular electrical heating | ||||

Stirring method | Mechanical stirring | ||||

Material | Stainless steel 304, 316 | ||||

Contact Us Now

WhatsApp:

Email:

Address:

19/F, Block B, Guohong Mansion, Hi-Tech Development Zone, Zhengzhou City, Henan Province, China