Glass Pressure Reactors: The Transparent Powerhouse of Modern Chemistry

Discover how these scientific marvels revolutionize chemical processes with safety, visibility, and precision

The Clear Advantage in Chemical Processing

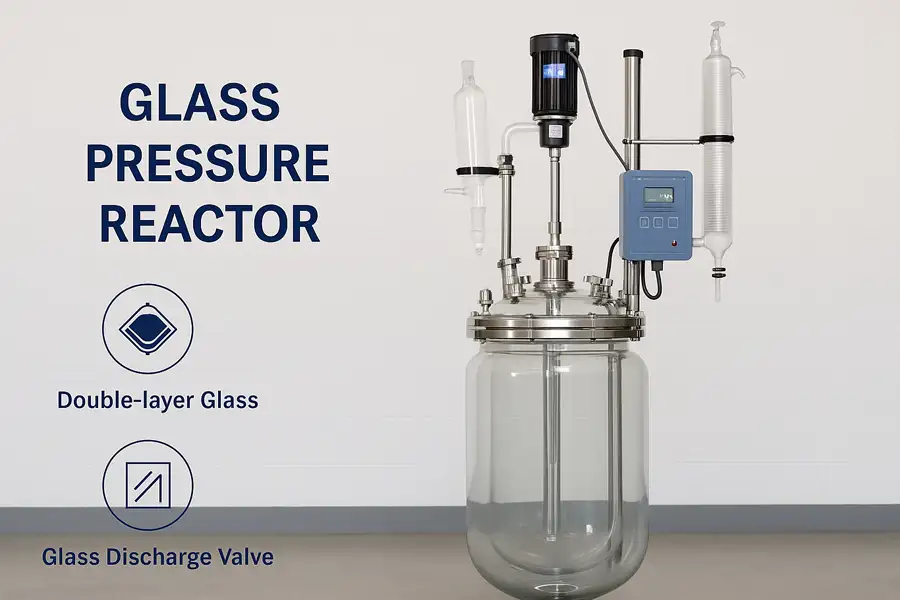

Picture this: You're conducting a delicate chemical reaction that requires precise temperature control, pressure monitoring, and visual observation. What tool makes this possible? The glass pressure reactor - a critical piece of equipment in modern laboratories and industrial settings.

Unlike their opaque counterparts, glass pressure reactors provide a unique combination of transparency and resilience. They allow scientists to literally see chemistry in action while safely containing reactions under pressure.

From pharmaceutical development to material science, these reactors have become indispensable. According to the American Chemical Society, over 85% of research laboratories now utilize glass reactors for at least part of their process development.

Why would someone choose a glass reactor over stainless steel?

The answer lies in two critical factors: visibility and chemical compatibility. Glass allows researchers to monitor reactions in real-time - seeing color changes, phase separations, and precipitations as they happen. Additionally, borosilicate glass offers exceptional resistance to a wide range of chemicals, especially corrosive substances that might degrade metal reactors over time. This combination of transparency and durability makes glass reactors invaluable for process development and optimization.

Why Glass Pressure Reactors Shine

Real-Time Visual Monitoring

Witness reactions as they unfold - see color changes, phase separations, and precipitations without interrupting the process. This visual feedback is invaluable for optimizing reactions and troubleshooting issues.

Superior Chemical Resistance

Borosilicate glass withstands corrosive acids, bases, and solvents that would degrade metal reactors. A study by the Chemical Safety Board showed glass reactors have 40% fewer corrosion-related failures than comparable metal systems.

Long-Term Value Champion

Saving Money Is The Last Word, And It Is Worth Investing In Buying! While the initial investment might be higher, glass reactors offer exceptional longevity and lower maintenance costs. Their transparency reduces the need for sampling, and their durability means fewer replacements.

Where Glass Pressure Reactors Excel

Glass pressure reactors have become essential in numerous industries:

Pharmaceuticals: Developing new drugs and optimizing synthesis pathways

Specialty Chemicals: Creating high-value compounds with precision

Agrochemicals: Developing safer, more effective pesticides and fertilizers

Industry Insight

"The ability to visually monitor reactions under pressure has reduced our process development time by an average of 30%. When you consider that each day saved in development can translate to millions in early market entry, the value of glass reactors becomes crystal clear." - Dr. Elena Rodriguez, Process Chemistry Director

How do glass reactors handle high-pressure situations safely?

Modern glass pressure reactors are engineering marvels designed with multiple safety layers. They feature reinforced borosilicate glass that can withstand pressures up to 10 bar (145 psi), pressure relief valves that automatically release excess pressure, and protective shields as secondary containment. Additionally, manufacturers subject each reactor to pressure tests at 150% of their rated capacity. This multi-layered approach ensures that even under demanding conditions, safety remains paramount.

Choosing Your Perfect Glass Reactor

Selecting the right reactor depends on your specific needs. Consider these key factors:

| Capacity | Typical Applications | Recommended Models |

|---|---|---|

| 1L | Small-scale research, screening reactions | 1L Jacketed Glass Reactor |

| 5L | Process development, intermediate scaling | 5L Jacketed Glass Reactor |

| 10L-20L | Pilot production, small batch manufacturing | 10L and 20L Jacketed Glass Reactors |

| 50L-100L | Commercial production, large-scale synthesis | 50L and 100L Jacketed Glass Reactors |

Key Selection Considerations

Temperature Range: Ensure the reactor can handle your process temperatures

Pressure Rating: Match to your maximum operating pressure

Chemical Compatibility: Verify resistance to your specific chemicals

Accessories: Consider stirrers, condensers, and sampling ports

Ready to Transform Your Chemical Processes?

Glass pressure reactors represent the perfect marriage of scientific innovation and practical engineering. They provide the visibility researchers need with the robustness industrial processes demand.

What's the first step in implementing glass reactor technology?

Begin with a thorough assessment of your process requirements - volume, pressure, temperature, and chemical compatibility. Then consult with specialists who can recommend the optimal configuration. Many laboratories start with a versatile 5L jacketed glass reactor that balances capacity with flexibility for various applications.