Glass Reactors: Science You Can See

Transparent, versatile, and critical to chemical breakthroughs worldwide

Discover why scientists trust glass reactors for pharmaceutical research, cosmetics development, and chemical engineering breakthroughs.

See Inside Your Reactions

What Are Glass Vessel Chemical Reactors?

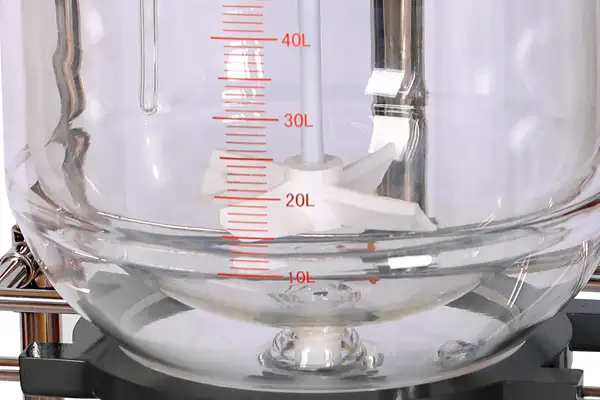

Picture a transparent, high-performance workspace where chemical reactions happen safely and visibly. That's exactly what glass reactors deliver!

Glass reactors—specifically borosilicate glass vessels—offer a revolutionary window into chemical processes that metal containers simply can't match. Their transparent walls aren't just a cool feature; they're a fundamental advantage that lets researchers monitor reactions in real-time without opening vessels or disrupting processes.

What separates these from ordinary glass? Their engineering. Modern chemical reactors use specialized borosilicate glass (think Pyrex® on steroids) designed to handle extreme conditions:

Temperatures from -80°C to +200°C

Aggressive acids, alkalis and solvents

Vacuum pressures down to 0.095 mbar

Constant thermal cycling stresses

Why Glass Vessels Win Every Time

Glass reactors aren't just about transparency—they're comprehensive chemical workhorses. Consider why major pharmaceutical companies are scaling up their glass reactor installations:

Reactive Transparency Power

Watch phase separations, crystallization points, and unexpected precipitates as they develop—critical for process optimization.

Corrosion Resistance Champion

Borosilicate glass handles HCl, HNO3, and NaOH solutions where metal would falter—extending equipment lifetime 3× according to MIT materials research.

Temperature Control Mastery

Jacketed systems circulate heating/cooling fluids around the reaction chamber, achieving ±0.5°C stability—vital for enzymatic reactions or polymerizations where ±1°C ruins batch consistency.

Where Glass Reactors Outperform Everything Else

Pharmaceutical Synthesis

Crucial for developing APIs where reaction monitoring prevents expensive bad batches. Glass's purity prevents metal contamination that ruins sensitive formulations.

Perfect fit: Crystallization Reactor Systems for purification stages

Chemical Process Research

Scale-up studies thrive with visible flow patterns before committing to stainless steel production vessels. Save weeks in process validation!

Recommended: Modular Glass Reactor Systems for versatility

Academic Research & Training

Students learn chemical behavior visually—seeing emulsion formations or precipitation teaches more than textbook diagrams ever could.

Entry point: 1L Glass Reactor Units perfect for university labs

Balance scale needs! 5L units (view 5L options) handle discovery-phase volumes economically while 10L (see 10L designs) suits process development. MIT's chemical engineering department found teams using appropriately-sized reactors reduced materials costs by 18-31%.

Common Glass Reactor Capacities

Glass Reactors vs. Stainless Steel: No Contest

When visual insight matters more than brute strength, glass dominates. Here's the data-driven reality:

| Feature | Glass Vessels | Stainless Steel |

|---|---|---|

| Material Cost (Avg) | ★★★ (Lower) | ★★☆ (Higher) |

| Visual Monitoring | Perfect 360° visibility | None - Blind operation |

| Chemical Compatibility | Resists acids/HF exception | Superior with HCl/HF |

| Reaction Scale Flexibility | Typically ≤100L | Up to 10,000L+ |

| Maintenance/Cleaning | Visual inspection simplifies | Requires disassembly |

| Thermal Shock Resistance | Limited rapid ΔT | Excellent performance |

"While stainless steel reactors excel at industrial-scale production, glass is undefeated for research visibility."

Ready to See Your Chemistry Clearly?

Upgrade to a glass reactor system and transform how you develop processes

Explore Glass Reactor Solutions →