The Magic of Lab Glass Reactors: Where Science Meets Transparency

Discover why glass reactors are revolutionizing chemistry labs worldwide with their unique combination of visibility, versatility, and precision

Explore ReactorsThe Clear Advantage: Why Glass Reigns Supreme

In the fascinating world of chemical research and development, the lab glass reactor stands as an unsung hero - the transparent workhorse that powers innovation across countless industries.

Imagine watching chemical reactions unfold like a beautifully choreographed dance. That's the magic of glass reactors! Unlike their opaque counterparts, these scientific marvels offer a front-row seat to chemical transformations. This visibility isn't just about satisfying scientific curiosity - it's a critical feature that enables researchers to monitor reactions in real-time, identify phase changes, and catch potential issues before they escalate.

What makes glass reactors superior for sensitive chemical processes?

The answer lies in their unparalleled chemical inertness. Glass, particularly borosilicate glass, creates an ultra-pure environment that won't interfere with even the most sensitive reactions. This means no unexpected side reactions, no metallic contamination, and no catalytic effects that could skew your results. When precision matters (and when doesn't it in chemistry?), glass provides the uncompromised environment researchers need.

Jacketed Brilliance: Temperature Control Perfected

At the heart of every high-performance glass reactor is its jacket system - the unsung hero of temperature management. This ingenious design creates a thermal envelope around the reaction vessel, allowing precise heating or cooling fluids to circulate and maintain exact temperatures.

Why does this matter? Consider that according to the American Chemical Society, over 65% of chemical reactions are temperature-sensitive - a variation of just a few degrees can mean the difference between a successful synthesis and a failed experiment. The jacketed design eliminates hot and cold spots, providing uniform thermal transfer that stainless steel reactors struggle to match.

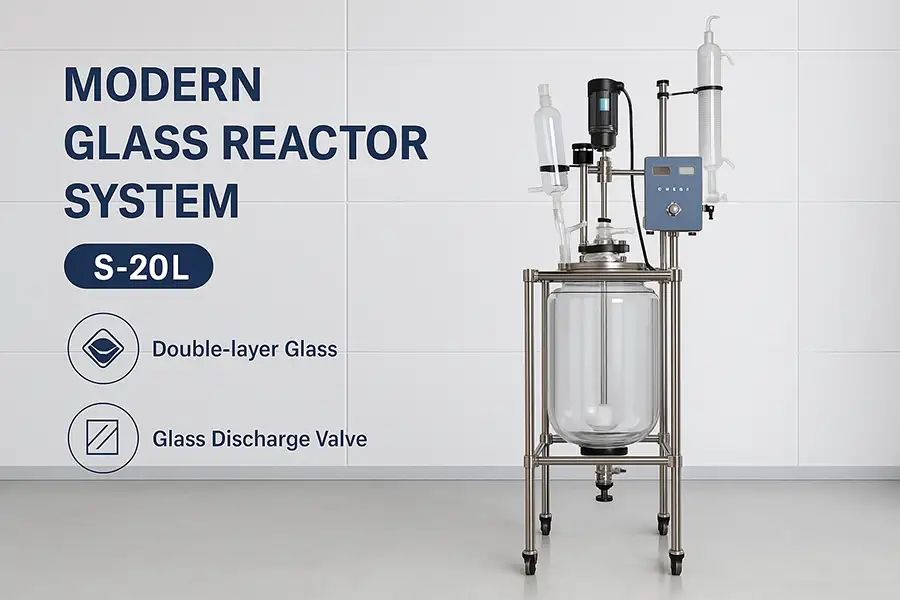

Size Matters: Finding Your Perfect Fit

From modest 1L units perfect for initial exploratory work to robust 100L systems designed for pilot-scale production, glass reactors scale beautifully to meet your needs. The most popular sizes include:

1L jacketed glass reactor - The compact powerhouse ideal for screening reactions

5L glass reactor - The "Goldilocks" size for most lab applications

10L jacketed glass reactor - Perfect for process development and scale-up studies

Larger systems - For pilot production and specialized applications

What size glass reactor dominates research laboratories?

The 5L capacity strikes the perfect balance for most research settings. It's large enough to produce meaningful quantities for analysis, yet small enough for efficient setup, cleaning, and solvent recovery. Industry surveys show that nearly 60% of academic and industrial labs consider 5L as their primary workhorse reactor size.

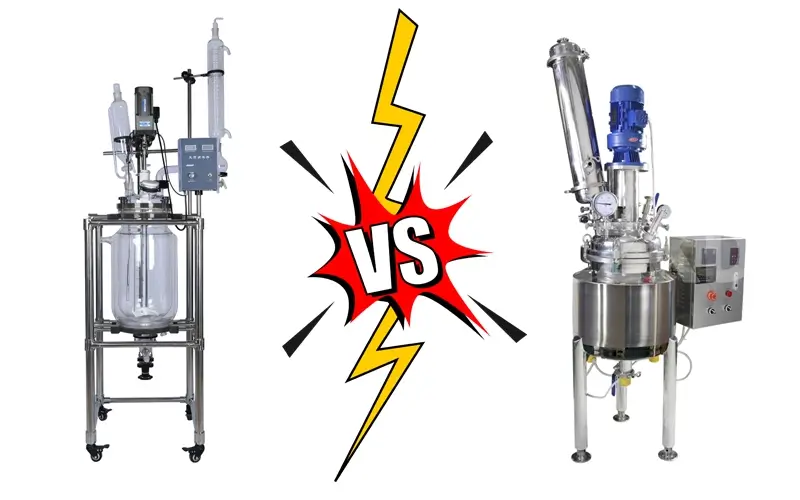

The Great Debate: Glass vs. Stainless Steel

| Feature | Glass Reactors | Stainless Steel Reactors |

|---|---|---|

| Visibility | Excellent | None |

| Chemical Resistance | Exceptional | Good |

| Corrosion Resistance | Excellent | Varies |

| Temperature Response | Rapid | Slower |

| Reaction Monitoring | Direct visual | Requires sensors |

| Initial Investment | Moderate | Higher |

Saving Money Is The Last Word, And It Is Worth Investing In Buying!

Let's talk dollars and sense. While the initial price tag of a quality glass reactor might give some lab managers pause, the long-term economics tell a compelling story. Consider these points:

Error Reduction

Visual monitoring catches issues early, preventing costly failed batches

Material Savings

No contamination means no wasted expensive reagents

Longevity

Properly maintained glass reactors last decades

According to a MIT Laboratory Efficiency Study, labs using glass reactors reported 23% lower operational costs over a 5-year period compared to stainless steel alternatives. The transparency advantage alone can reduce reaction optimization time by up to 40%!

How long can a quality glass reactor realistically last?

With proper care and maintenance, a borosilicate glass reactor can deliver reliable service for 15-20 years. The key is investing in quality construction from the outset and following proper operating protocols. Many university chemistry departments still use glass reactors purchased in the 1990s!

"Switching to jacketed glass reactors transformed our research capabilities. We reduced process development time by 30% simply because we could actually see what was happening in real-time. The ability to spot crystallization endpoints visually has been revolutionary."

The Future Is Clear: Glass Reactors in Modern Science

As chemical research pushes into increasingly complex territories - from nanomaterial synthesis to bioconjugates - the advantages of glass reactors become even more pronounced. The pharmaceutical industry's shift toward continuous manufacturing has created new opportunities for glass reactor technology, with modular systems enabling seamless scale-up from discovery to production.

According to recent market analysis, the global glass reactor market is projected to grow at 6.8% CAGR through 2028, significantly outpacing the broader laboratory equipment sector. This growth is largely driven by increased R&D investment in pharmaceuticals and specialty chemicals.

Find Your Perfect Glass Reactor

Ready to Transform Your Lab?

Join thousands of researchers who've discovered the glass reactor advantage

Explore Our Reactor CollectionMaintenance Mastery: Keeping Your Glass Reactor Pristine

To maximize your investment, proper maintenance is key. Follow these best practices:

Clean Immediately - Never let residues dry inside the reactor

Use Proper Brushes - Nylon or PTFE-coated brushes prevent scratching

Avoid Thermal Shock - Gradually change temperatures

Inspect Regularly - Check for scratches or weak points

Store Correctly - Keep in padded storage when not in use

Remember that while glass reactors are remarkably durable, they're not indestructible. Proper handling during setup and cleaning prevents 90% of potential issues. Investing in quality clamps and support stands pays dividends in longevity.

Pro Tip:

For stubborn residues, try a warm solution of laboratory-grade citric acid. It's effective on most organic deposits and far gentler on glass than harsh solvents or abrasive cleaners.

Key Advantages at a Glance

Real-time visual monitoring

Exceptional chemical resistance

Rapid temperature response

Easy cleaning and maintenance

Cost-effective long-term solution

Compatibility with diverse reactions

Applications Spotlight

Pharmaceutical synthesis

Chemical process development

Nanomaterial production

Polymer research

Catalyst testing

Extraction processes

Distillation studies

Crystallization optimization