Stainless Steel Chemical Reactor

The ultimate technical resource for chemical engineers, processing technicians, and industrial designers. Learn everything about stainless steel chemical reactors, including their industrial applications, benefits, and how they compare to other reactor types.

A stainless steel chemical reactor is engineered to manage chemical reactions under precisely controlled conditions of temperature, pressure, and agitation. These sophisticated systems serve as the backbone of modern chemical processing and are indispensable across sectors from pharmaceuticals to biofuels.

Industrial-grade stainless steel chemical reactor capable of handling high-pressure reactions

Fundamentals of Stainless Steel Reactors

Characterized by their exceptionally durable construction, stainless steel reactors are designed for batch, semi-batch, or continuous operation modes. The selection of stainless steel—with its unparalleled corrosion resistance and structural integrity—makes it the material of choice for applications demanding absolute purity and longevity.

Yes. With engineering-grade stainless steel alloys, these reactors can operate effectively from cryogenic temperatures (-200°C) to extreme heat conditions up to 500°C, depending on material selection and design specifications.

The Scientific Advantage of Stainless Steel

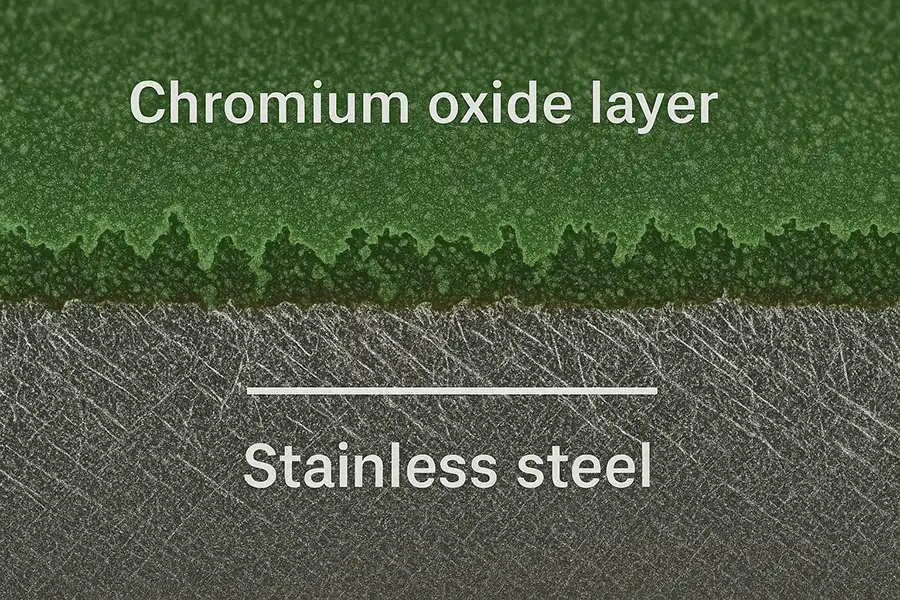

Stainless steel's chemical resistance originates from its chromium content, which forms a microscopic chromium oxide layer on exposure to oxygen, creating an impervious barrier against corrosion. This protective mechanism gives stainless steel reactors exceptional resistance to both acidic and alkaline environments.

Microscopic chromium oxide layer formation on stainless steel

56M+

Metric tons of global stainless steel produced (2021)

92%

Of pharmaceutical manufacturing processes utilize stainless steel reactors

30+

Years of operational life with proper maintenance practices

Industrial Applications

Pharmaceutical & biotech manufacturing

Specialty chemical production

Food & beverage processing (GMP facilities)

Petrochemical & refinement processes

Polymer synthesis & material science

Bioenergy & sustainable fuel production

While glass reactors offer visibility and chemical inertness—making them suitable for laboratory applications like the 1L jacketed glass reactor—stainless steel reactors provide superior structural integrity, higher pressure capabilities (up to 500 psi), and temperature stability for industrial-scale operations. Glass reactors typically serve R&D purposes before process scale-up to stainless systems.

Reactor Classification & Specifications

| Reactor Type | Scale & Utilization | Key Advantages | Pressure Range |

|---|---|---|---|

| Batch Reactor | Small to medium production • Multi-product facilities | Operational flexibility • Simplified cleaning validation | 0-150 psi |

| Continuous Stirred Tank (CSTR) | High-volume continuous production • Steady-state processes | Consistent product quality • Lower labor requirements | 50-300 psi |

| High Pressure Reactor | Specialty synthesis • Hydrogenation • Gas-liquid reactions | Enhanced reaction kinetics • Superior mass transfer | 300-3000 psi |

Material Advantages Over Alternatives

Corrosion performance: Superior resistance to chloride stress cracking compared to standard alloys

Thermal management: Exceptional heat distribution capabilities

Product integrity: Non-reactive surface preserves chemical purity

Operational longevity: Service life exceeds glass-lined reactors by 40%

Structural properties: High strength-to-weight ratio enables cost-effective support systems

Stainless steel reactor vessel with integrated thermal control systems

While stainless steel reactors cover over 80% of chemical processing applications, materials selection depends on specific chemical compatibilities. Highly corrosive hydrofluoric acid applications require glass-lined steel, and halogen compounds may require specialized nickel alloys. The 50L jacketed glass reactor offers an intermediate solution for pilot-scale applications requiring observation capabilities.

Industry Evolution & Future Outlook

Digital transformation is revolutionizing reactor design with AI-driven process optimization and Industry 4.0 integration. MIT research predicts 40% of chemical manufacturing will incorporate machine learning for predictive maintenance and reaction optimization by 2027. Future trends focus on modular systems for flexible manufacturing and sustainability integration.

Related Processing Equipment

Explore complementary systems for comprehensive process solutions:

Reactor Selection Guide

Choosing the appropriate reactor involves comprehensive assessment across multiple parameters:

Selection Criteria

Chemical compatibility analysis

Reaction kinetics & thermodynamics

Pressure-temperature profile requirements

Throughput capacities & upscaling paths

Clean-in-place (CIP) capabilities

Regulatory compliance requirements

Validation Requirements

GAMP 5 lifecycle compliance

Material traceability & certifications

Mechanical integrity testing protocols

Surface roughness validation (Ra ≤ 0.5 μm)

Automation system IQ/OQ/PQ documentation