What Determines the Price of a Chemical Reactor?

Trying to budget for a new chemical reactor is tough. Prices seem to be all over the place, making it hard to know if you're getting a fair deal.

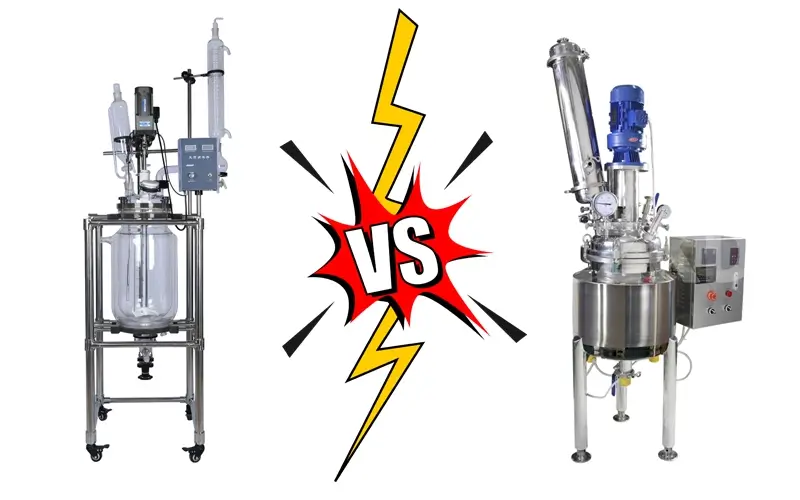

A chemical reactor's price depends on its material, size, and features. For example, a small lab glass reactor might cost a few thousand dollars, while a large industrial stainless steel reactor can cost tens of thousands. Key factors include volume, pressure rating, and automation level.

As a manufacturer with over 16 years of experience, I've talked to thousands of customers. I know that understanding the final price is one of the biggest hurdles you face. You need the right equipment for your process, but you also need it to fit your budget. It's a balancing act. In this article, I want to pull back the curtain and show you exactly what goes into the price of a reactor, so you can make a confident and informed choice for your lab or facility.

What Factors Influence the Price of a Glass Reactor?

You need the visibility a glass reactor offers, but wonder why prices differ so much. It's frustrating when you see one model for one price and a similar one for double.

The price of a glass reactor is mainly set by its size, the quality of the glass, and its components. Larger volumes, thicker borosilicate glass for higher pressure, and features like explosion-proof motors will increase the cost. Base models are cheaper, while customized systems cost more.

When you're looking at a glass reactor, you're not just buying a glass vessel. You're buying a complete system designed for precise chemical processes. Let's break down where the costs come from. First and foremost is the volume. It's simple: more glass costs more money. A small 1L glass reactor for a small lab is much more affordable than a 100L glass reactor for pilot-scale production. The type of glass is also critical. We use high-borosilicate glass (3.3) because it's strong and resists chemical corrosion and thermal shock. The jacketed design, which allows for heating and cooling, adds another layer of complexity and cost compared to a single-wall vessel. We make sure these are built to last.

Key Cost Drivers for Glass Reactors

| Feature | Impact on Price | Why It Matters |

|---|---|---|

| Volume (Size) | High | Larger reactors require more material and more robust support structures. |

| Motor & Stirrer | Medium | An explosion-proof motor for volatile solvents costs more than a standard one. |

| Lid & Ports | Medium | More ports for adding sensors, funnels, or condensers add to the manufacturing complexity. |

| Ancillary Equipment | High | The total cost rises when you add a chiller, heater, or vacuum pump to the system. |

How is the Price of a Stainless Steel Reactor Determined?

Your process demands higher pressure or temperature than glass can handle. But the price range for stainless steel reactors is wide, leaving you unsure of what a fair price is.

A stainless steel reactor's price is driven by the grade of steel (304 vs. 316L), its volume, and its pressure rating. Higher-grade, corrosion-resistant 316L steel costs more. Thicker walls for higher pressures and larger volumes also significantly increase the price of the vessel.

Stainless steel reactors are the workhorses of many industries, from pharmaceuticals to food production. Their price reflects their durability and capability. The biggest factor is the material itself. While SS304 is a common and cost-effective choice, many of our clients in the pharmaceutical and biotech industries require SS316L. This grade has added molybdenum, which greatly improves its resistance to chlorides and other corrosive agents, but it also costs more. The next major factor is the pressure rating. To handle higher pressures, the reactor walls must be thicker, and the welding and sealing technology must be more advanced. This requires more material and highly skilled labor, directly impacting the final cost. We take pride in our welding, as it's key to the safety and longevity of the reactor. Finally, the internal finish, or polish, matters. A mirror finish required for sanitary applications is more labor-intensive to produce than a standard industrial finish.

Core Factors for Stainless Steel Reactor Costs

Understanding these elements helps clarify the price tag:

Steel Grade: SS316L offers superior corrosion resistance compared to SS304, making it essential for certain applications but at a higher cost.

Wall Thickness: This is directly related to the maximum pressure the reactor can safely handle. More pressure means thicker, more expensive walls.

Polishing and Finish: A mirror-polished, sanitary-grade finish required for GMP applications involves more steps and manual labor than a standard industrial finish.

Jacket Design: A dimple jacket is often more efficient for heat transfer and can handle higher pressures than a conventional jacket, but its manufacturing is more complex.

What Makes High-Pressure Reactors More Expensive?

You need to run reactions under extreme conditions. You see the high prices for these reactors and worry about the investment, wondering what justifies the significant cost.

A high pressure reactor is more expensive due to its specialized materials, complex engineering, and critical safety features. They are built from robust alloys with thick walls, use advanced sealing technology like magnetic couplings, and include essential safety mechanisms like rupture discs, all adding to the cost.

When you're working with high-pressure reactions, safety is everything. That is what you are paying for in a high-pressure reactor. These are not just simple vessels; they are highly engineered systems designed to contain powerful forces safely. The cost starts with the materials. We often use special steel alloys that can withstand extreme pressures and temperatures without failing. The walls of these reactors are incredibly thick. The real engineering challenge, and a big part of the cost, is in the sealing. You can't just use a simple gasket. We use advanced magnetic drive couplings to turn the stirrer. This creates a seal with no physical penetration, eliminating the risk of leaks at high pressure. I've seen the consequences of failed seals, and it’s not something we ever compromise on. Every reactor also comes with mandatory safety features, like a pressure relief valve and a rupture disc, which are non-negotiable for protecting the user and the lab.

Why Safety and Engineering Increase Cost

| Component | Impact on Price | Reason for Cost |

|---|---|---|

| Thick-Walled Vessel | High | Requires significantly more high-strength material to contain pressure. |

| Magnetic Drive Coupling | High | Complex engineering to provide a leak-proof seal for the stirrer under pressure. |

| Safety Features | Medium | Rupture discs, relief valves, and high-pressure sensors are essential for safe operation. |

| Certifications | Medium | Often requires pressure vessel certifications, which involves rigorous testing and documentation. |

Conclusion

A reactor's price is a mix of its material, size, and features. Understanding these key factors helps you choose the right equipment that fits your needs and your budget.