What Makes a Glass Reactor System So Important for Your Laboratory's Success?

Struggling with opaque reaction vessels? Need to see your chemical processes clearly? A glass reactor offers unmatched visibility and control, solving these common lab challenges.

A glass reactor system is vital for labs because it allows direct observation of chemical reactions, ensures high purity due to its inertness, and offers flexibility for various processes like synthesis, distillation, and crystallization, which we've perfected over 16 years of manufacturing.

As a company that has specialized in producing and exporting lab equipment for over 16 years, we understand the details that matter. We've seen many labs transform their research and production capabilities by choosing the right glass reactor. It's more than just glassware; it's a complete system designed for precision and reliability. We want to share some of that experience with you.

What Exactly is a Glass Reactor System and How Does It Function?

Confused by the components of a reactor? Wondering how it all comes together to create a controlled reaction environment? We can explain this complex system in simple terms.

A glass reactor system is a setup where a glass vessel is equipped with stirrers, condensers, and temperature controls to perform chemical reactions under monitored conditions. It allows for safe and efficient mixing, heating, cooling, and observation.

Let me break down how these systems work. We've designed and built thousands of these, so I know them inside out. Think of it as a highly controlled environment for your chemical experiments or small-scale production.

Core Components and Their Roles

Most glass reactor systems we manufacture have several key parts:

The Glass Vessel: This is usually made from high borosilicate glass 3.3, which is great because it resists most chemicals and can handle big temperature changes. We offer various sizes, from small benchtop units for research to larger pilot-scale reactors.

Stirring System: This includes a motor, a stirrer (anchor, propeller, etc.), and a seal. It ensures your reactants are mixed well for a uniform reaction. We offer different stirring speeds and torque options.

Lid/Cover: This seals the vessel and has ports for adding materials, inserting sensors (like temperature probes), connecting condensers, and vacuum lines.

Condenser: This helps to cool vapors and return them to the vessel as liquid (reflux) or to collect distilled products. We have various designs depending on the application.

Temperature Control Unit: This can be a heating/cooling circulator that pumps fluid through a jacketed vessel, or a heating mantle for single-layer vessels. Precise temperature is key, and our systems are designed for that.

Supporting Frame: Usually stainless steel, this holds all components securely.

The Process Flow

Imagine you're setting up a reaction. First, you'd assemble the system, ensuring all connections are tight. Then, you add your reactants to the vessel. You set your desired temperature and stirring speed. As the reaction proceeds, you can watch it through the glass. If it produces vapors, the condenser does its job. We've made sure our systems are easy to operate and monitor, which is something our clients in 87 countries really appreciate.

Why Should Your Laboratory Consider a Glass Reactor Over Other Types?

Are you weighing material options for your next reactor? Wondering if glass truly meets your demanding chemical applications? The unique benefits of glass often make it the superior choice.

Laboratories should choose glass reactors for their exceptional chemical resistance, transparency for process monitoring, ease of cleaning, and ability to handle a wide range of temperatures and vacuum, ensuring product purity and experimental accuracy. We see this value daily.

Over my 16 years in this business, especially focusing on international exports, I've talked to many researchers and production managers. They often choose glass for very good reasons, and our ISO9001 and CE certifications back up the quality we provide.

Key Advantages We Emphasize

Visibility: This is a big one. Being able to see what's happening inside – color changes, phase separations, crystallization – is invaluable. You can't get that with a stainless steel reactor.

Chemical Inertness: Borosilicate glass 3.3 is highly resistant to most chemicals. This means no contamination of your product and no corrosion of the reactor itself, which is crucial for our clients in pharma and fine chemicals.

Smooth Surface & Ease of Cleaning: Glass has a very smooth surface, which minimizes residue buildup and makes cleaning much easier. This is important for preventing cross-contamination between batches.

Versatility: Glass reactors can be used for a wide range of applications, from simple mixing to complex multi-step syntheses, distillation, and crystallization. Our designs accommodate various setups.

Good Thermal Properties: While not as conductive as metal, jacketed glass reactors allow for efficient heat transfer when paired with a good circulator. Glass also handles significant temperature differences, though thermal shock must be avoided.

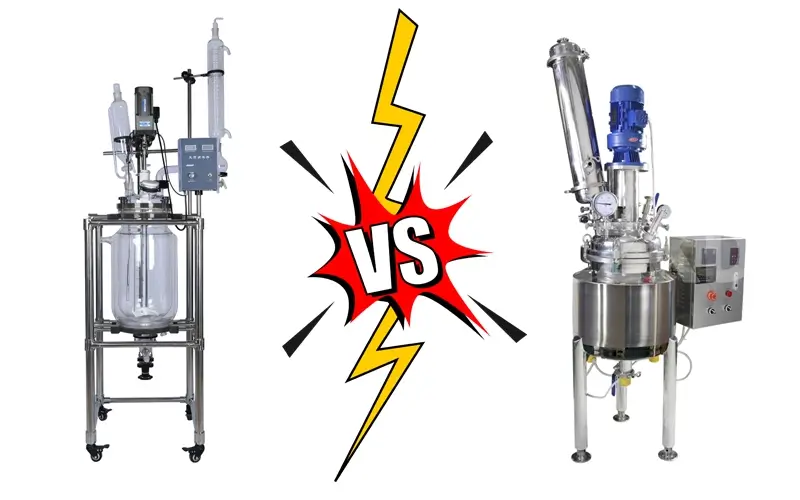

Glass vs. Stainless Steel: A Quick Look

| Feature | Glass Reactor | Stainless Steel Reactor |

|---|---|---|

| Visibility | Excellent | None (unless sight glass added) |

| Chemical Resistance | Excellent (except HF, strong alkali) | Good, but can corrode with certain acids/chlorides |

| Pressure Rating | Moderate (typically up to 0.5-1 bar) | Very High |

| Temperature Range | Wide (e.g., -80°C to 250°C) | Very Wide |

| Cleanability | Excellent | Good, but can have crevices |

While stainless steel is better for very high pressures, for many lab and pilot applications, the benefits of glass, especially visibility and inertness, are preferred. This is a common feedback point we get during the 15 international exhibitions we regularly attend.

Which Key Industries Rely on Glass Reactor Systems for Their Processes?

Curious if glass reactors are relevant to your field? Unsure how these systems are applied in real-world industrial and research settings? Their versatility might surprise you.

Glass reactors are crucial in chemical and pharmaceutical companies for synthesis and purification, biotech for biomolecule processing, universities for research and teaching, and the food industry for extraction and quality control, among others. We serve them all.

As an integrated factory and exporter, we've supplied our glass reactor systems to a wide array of industries across 87 countries. It's always fascinating to see the diverse applications. Here are some of the main sectors:

Chemical & Pharmaceutical Companies

These are probably our biggest customers. They use our reactors for everything from research and development of new drug compounds to pilot-scale production. Think synthesis of active pharmaceutical ingredients (APIs), crystallization, purification processes, and solvent recovery. The inert nature of glass and the ability to visually monitor are critical here.

Biotechnology & Life Science Companies

In biotech, our reactors might be used for small-scale cell culture (though bioreactors are more specialized here), extraction of natural products, or processing sensitive biomolecules. Again, cleanliness and inertness are key. Freeze dryers often complement reactors in this field, which is another core product for us.

Academic Universities & Research Institutions

University labs worldwide use our glass reactors for teaching and fundamental research. They are perfect for students to learn about chemical processes due to their visibility. Researchers appreciate the flexibility to adapt the systems for various experiments in chemistry, materials science, and more.

Food & Beverage Industry

This industry uses glass reactors for extracting flavors and fragrances, concentrating liquids, and in quality control labs. For example, developing new food additives or ensuring the consistency of a beverage. Spray dryers and rotary evaporators are also popular here, which we also specialize in.

Cannabis & Hemp Processing

A growing market for us involves cannabis and hemp processing. Our glass reactors, often larger scale, are used for extraction of cannabinoids, winterization, and distillation processes. The ability to handle solvents safely and efficiently is important.

The common thread is the need for controlled, visible, and pure reaction conditions, something our "Made in China + International Quality" approach delivers reliably.

How Can You Select the Perfect Glass Reactor Tailored to Your Specific Needs?

Feeling overwhelmed by options when choosing a reactor? Unsure what specifications truly matter for your application? Selecting the right one is easier with some guidance.

To select the perfect glass reactor, consider your required volume, operating temperature and pressure ranges, stirring needs, material compatibility, and whether you need a single-layer or jacketed system. Our team often helps customers evaluate these factors.

Choosing the right glass reactor is a critical decision. As a manufacturer with over 16 years of experience, we've helped thousands of customers make this choice. Here are the main things I always tell them to think about:

1. Volume and Scale

What quantity of material will you be working with? We offer reactors from 500mL up to 200L or even larger for custom projects. It's usually good to choose a size where your typical working volume is between 50-80% of the reactor's total capacity.

2. Temperature Requirements

What temperatures will your reactions run at? This will influence the type of glass (all ours are high borosilicate 3.3, good from -80°C to 250°C typically) and importantly, the heating/cooling circulator you pair with a jacketed reactor. For very high temperatures, other considerations might come into play.

3. Pressure and Vacuum Needs

Standard glass reactors are designed for atmospheric pressure or moderate vacuum (down to a few mbar). If you need high pressure, a glass-lined steel or full steel reactor is usually necessary. We always clarify pressure limits for safety.

4. Stirring Mechanism

What kind of mixing do you need? Viscosity of your material, desired mixing pattern (gentle agitation vs. high shear) will determine the type of stirrer (anchor, propeller, turbine, PTFE-coated) and the motor power. We offer various options and can customize.

5. Jacketed vs. Non-Jacketed

A jacketed glass reactor has an outer shell where heating/cooling fluid circulates for precise temperature control. This is the most common type we sell. Non-jacketed (single-layer) reactors are simpler and often heated with a mantle, but offer less precise control.

6. Number of Lid Ports

Consider what you need to connect: stirrer, condenser, dropping funnel, temperature probe, vacuum, nitrogen inlet, pH probe, etc. Our standard lids come with multiple ports, but we can customize these based on your specific experimental setup.

More than 50% of our engineers are fluent in English, and they are always ready to discuss these details to ensure you get a system that truly fits your work. It's part of our commitment to providing customized, high-cost-performance equipment.

What Are the Best Practices for Maintaining Your Glass Reactor System?

Worried about damaging delicate glassware? Want to ensure your reactor performs optimally for years? Proper maintenance is key, and simpler than you might think with our systems.

Best practices for maintaining a glass reactor include regular cleaning, careful handling of glass parts to avoid thermal shock and mechanical stress, checking seals and connections, and following manufacturer guidelines for operation. This ensures longevity and safety.

We build our glass reactors to be robust, but like any precision instrument, they require some care to ensure a long and productive life. Here's what our 24/7 after-sales support team often advises clients, drawing from our extensive export experience:

Daily and Post-Reaction Care

Clean Promptly: Don't let residues dry and harden. Clean the vessel and components soon after use with appropriate solvents. Our smooth glass makes this easier.

Inspect Glassware: Before each use, quickly check for any small chips or cracks, especially around ground glass joints. Damaged glassware should not be used under pressure or vacuum.

Handle with Care: Avoid hitting glass parts against hard surfaces. When assembling or disassembling, don't force joints. A little grease on ground glass joints helps.

Periodic Checks

Seals and Gaskets: Regularly inspect PTFE seals, O-rings, and gaskets for wear or damage. Replace them if they look compressed, brittle, or torn to maintain vacuum integrity and prevent leaks. We supply all necessary spare parts.

Stirrer Assembly: Check that the stirrer motor operates smoothly and the stirrer shaft and seal are in good condition.

Frame and Clamps: Ensure the support frame is stable and all clamps holding the glassware are secure but not overly tightened, which can stress the glass.

Important "Don'ts"

Avoid Thermal Shock: Do not subject the glass to sudden extreme temperature changes. For example, don't pour very cold liquid into a hot vessel, or vice-versa. Heat and cool gradually, especially with larger vessels.

Don't Exceed Limits: Always operate within the specified temperature and pressure limits for your reactor.

Use Compatible Chemicals: While borosilicate glass is very resistant, avoid hydrofluoric acid, hot concentrated phosphoric acid, and strong hot alkalis, as these can etch the glass.

We offer a one-year warranty with free maintenance, and lifetime cost-price service for parts. Our goal is to minimize your maintenance costs and downtime. Taking these simple steps will help your "Made in China + International Quality" reactor serve you well for many years.

In summary, a glass reactor is a versatile, reliable tool for many labs, and choosing and maintaining one correctly ensures great results. We're here to help with that.