What Makes a Glass Vessel Chemical Reactor So Essential in the Lab?

Struggling with visibility in your chemical reactions? Unsure if your current setup handles diverse chemistries safely? It is a common lab challenge for many researchers and production managers.

A glass vessel chemical reactor is vital because it allows direct observation of reactions. It offers excellent chemical resistance and handles a wide range of temperatures and pressures. This makes it very versatile for research, development, and small-scale production. As a manufacturer with 16 years of export experience, we at Zhengzhou Keda (ZZKD) understand their true value in a lab.

If you have ever wondered how these reactors achieve such precise results, you are in the right place. Or maybe you want to know what makes them a key piece of equipment in modern labs. We have spent over 16 years perfecting these systems and exporting them globally. Let's explore why a glass reactor might be exactly what your work needs. We have seen them help so many customers. We believe they can help you too.

How Does a Glass Reactor Actually Work for Chemical Reactions?

Confused about what happens inside a glass reactor? Visualizing the mixing, heating, and reaction process can be tricky if you have not used one often. It can seem complex.

A glass reactor works by providing a controlled environment. Reactants are added to the vessel. They are stirred to mix them well. The vessel can be heated or cooled. The clear glass allows constant monitoring. This helps make sure conditions are perfect for your chemical process.

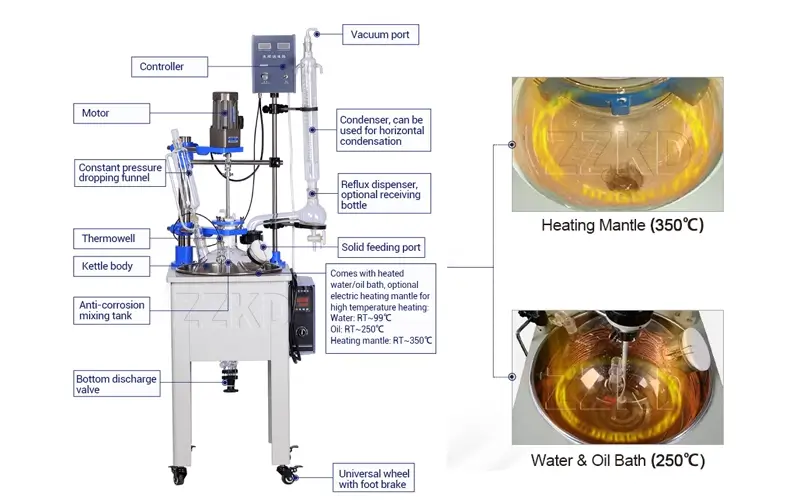

Understanding how a glass reactor functions is easier if we break it down. The main part is the glass vessel itself. This is where your chemicals go. Then, there is a stirring system. For our reactors, we usually use an overhead stirrer. This is powerful and can mix even thick liquids well. Good mixing is very important for most reactions to proceed efficiently.

Temperature control is another key aspect. Most of our glass reactors are jacketed. This means there is an outer layer around the main vessel. We can circulate hot oil, water, or cooling fluid in this jacket. This allows us to precisely control the temperature inside the vessel. We also include ports for temperature probes. So, you always know the exact temperature of your reaction. Some of our clients have very specific temperature needs. I remember one customer working on a sensitive crystallization process. Maintaining a stable temperature was critical for them. Our jacketed system provided that stability.

Many reactions also involve solvents that can evaporate. So, we always equip our reactors with condensers. These cool down any vapors and turn them back into liquid. This liquid then drips back into the reactor. This is called reflux. It saves your solvent and is important for safety too. For adding new chemicals during the reaction, there is usually a dropping funnel. This lets you add liquids slowly and in a controlled way. All these parts work together. They make complex chemistry more manageable and safer. Our long experience, and our ISO9001 and CE certifications, ensure these components are reliable and well-made.

What Are the Key Advantages of Using Glass for My Chemical Reactor?

Worried about whether your reactor material will affect your experiment? Choosing the wrong material can lead to contamination, poor results, or even safety issues in your lab.

Glass, especially borosilicate glass 3.3, offers great chemical resistance. It also gives excellent transparency for watching your process. Plus, it has good thermal stability. This makes it perfect for many chemical reactions. It reduces contamination and helps ensure reliable results. We have seen these benefits for years.

When we talk about glass reactors, we usually mean borosilicate glass. This type of glass has some really great properties for lab work. We have been making equipment from it for over 16 years. Here is why it is so good:

1. Amazing Chemical Resistance

Borosilicate glass does not react with most chemicals. You can use strong acids, solvents, and many other substances in it. It will not corrode or release impurities into your reaction. I recall a client who was having trouble with metallic ions leaching from their old reactor. Switching to one of our glass reactors solved their problem completely. This purity is vital, especially in pharmaceutical work.

2. You Can See Everything

This is a big one. Because glass is clear, you can watch your reaction as it happens. You can see color changes, if things are mixing well, or if anything unexpected is occurring. This visual feedback is so important. One researcher told me, "It's like having a window into my chemistry; I can stop a problem before it ruins my batch."

3. Handles Heat and Cold Well

Our glass reactors can handle a wide range of temperatures. They can also cope with sudden temperature changes, within limits, of course. This is what we call thermal shock resistance. We design them carefully for this. So, you can heat things up or cool them down as your process needs. We always give clear instructions on how to do this safely.

4. Easy to Clean

The surface of glass is very smooth. This means it is easy to clean thoroughly. Less material sticks to the sides. This reduces the chance of cross-contamination between different batches. This practical benefit saves time and ensures better quality results. It's something our customers appreciate.

5. Good for Vacuum Operations

Many chemical processes require a vacuum. Our glass reactor systems are designed to be vacuum-tight. We ensure all connections and seals are high quality. This is part of the rigorous testing we do to meet CE standards.

Which Industries Benefit Most from Using Glass Chemical Reactors?

Wondering if a glass reactor fits your industry's specific work? It is not always clear how versatile one piece of lab equipment can be across different fields.

Many industries benefit greatly. Chemical and pharmaceutical companies use them for synthesis and purification. Biotech, universities, food and beverage makers, and material science labs also rely heavily on glass reactors for research, development, and quality control. Our customer base at ZZKD spans all these sectors.

Over my 16 years in this business, exporting to 87 countries, I have seen our glass reactors used in so many interesting ways. It is a truly versatile piece of equipment. Here are some of the main industries that use them:

| Industry | Common Needs & Uses | Relevant ZZKD Products Mentioned |

|---|---|---|

| Chemical & Pharmaceutical Companies | Synthesis of new compounds, purification of active ingredients, process development, pilot-scale production, solvent recovery. They need reliable and non-reactive surfaces. | Glass Reactors, Rotary Evaporators, Distillation Systems, Temperature Control Units. |

| Biotechnology & Life Science Companies | Cell culture (smaller scale), extraction of biomolecules, sample preparation, purification of sensitive biological materials. Sterility and gentle processing can be important. | Glass Bioreactors (for some applications), Rotary Evaporators, Freeze Dryers. |

| Academic Universities & Research Institutions | A huge range of fundamental research in chemistry, biology, materials science. Also used in teaching labs for students to learn chemical processes. We've supplied countless university labs. | Full range: Glass Reactors, Rotary Evaporators, Heating Mantles, Chillers. |

| Food & Beverage Industry | Extracting flavors and fragrances, concentrating liquids, quality control testing, developing new products. Think about natural extracts or essential oils. | Rotary Evaporators, Glass Reactors (for R&D), Extraction Systems. |

| Cannabis & Hemp Processing Facilities | Extraction of cannabinoids and terpenes, solvent recovery, distillation for purification (like our short-path distillation systems), winterization. This is a rapidly growing area for us. | Large-scale Rotary Evaporators, Falling Film Evaporators, Short Path Distillation, Filter Reactors. |

| Materials Science & Nanotechnology Labs | Synthesizing new materials, polymer processing, solvent removal for nanoparticle preparation. Precision is key here. | Glass Reactors, Rotary Evaporators, High-Temperature Furnaces. |

Participating in 15 international exhibitions across 7 countries has allowed us to meet people from all these fields. It helps us understand their evolving needs. Our goal as a China-based factory and exporter is to provide "Made in China + International Quality" equipment that serves these diverse applications. Our 24/7 after-sales support team, with many English-speaking engineers, is always ready to help, no matter the industry.

Conclusion

Glass vessel chemical reactors are truly versatile, transparent, and chemically resistant tools. They are essential for many industries. They offer precise control for successful reactions and consistently reliable results.