What Makes Glass Lined Reactors So Essential for Modern Chemical Processing?

Struggling with material corrosion and product purity in your reactions? You need a reliable vessel that protects your process, but finding the right one can be a major headache.

A glass-lined reactor is a steel vessel with a fused glass interior. This design offers the best of both worlds: the strength of steel and the superior corrosion resistance of glass, making it ideal for handling harsh chemicals and ensuring high product purity in various industries.

Over my 16 years in this business, I've seen countless labs and production facilities transform their results simply by choosing the right equipment. The decision isn't just about a single piece of hardware; it's about the integrity of your entire operation. A reactor is the heart of your process, where synthesis, mixing, and reactions happen. Choosing a glass-lined model protects that heart from aggressive chemicals, ensuring what you produce is pure and uncontaminated. It’s a choice that pays off in reliability and quality, day after day.

Why is a Glass-Lined Reactor the Top Choice for Corrosive Environments?

Are you worried that aggressive acids or bases will ruin your expensive equipment? This fear can limit your chemical processes and slow down innovation, costing you time and money.

A glass-lined reactor is the premier choice because its inert glass surface is highly resistant to almost all acids, alkalis, and solvents. This prevents vessel degradation and metallic ion leaching, guaranteeing both equipment longevity and the purity of your final product, which is critical for pharmaceuticals.

Let's break down why this protection is so important. In my experience, customers in chemical and pharmaceutical fields face two big risks: equipment failure and product contamination. The glass lining directly tackles both. It's not just any glass; it's a special borosilicate formulation that we fuse to the steel shell at extremely high temperatures. This process creates a strong, seamless bond that can handle a lot. It offers incredible chemical resilience, which is a must-have for safe and clean operations. When you work with us, we don’t just sell you a product; we provide a solution that safeguards your entire process from start to finish. This gives you the confidence to run a wider range of chemical reactions without holding back.

The Science of Protection

The glass lining is essentially a shield. It prevents the reactive chemicals inside from ever touching the structural steel of the vessel. Think about what happens when an aggressive acid meets standard metal – corrosion begins immediately, introducing impurities and weakening the reactor. With a glass reactor, that simply doesn't happen. The glass layer is also non-stick and very smooth. This helps prevent materials from building up on the vessel walls, making cleaning easier and reducing the risk of cross-contamination between batches. It's a key feature for industries where purity is everything.

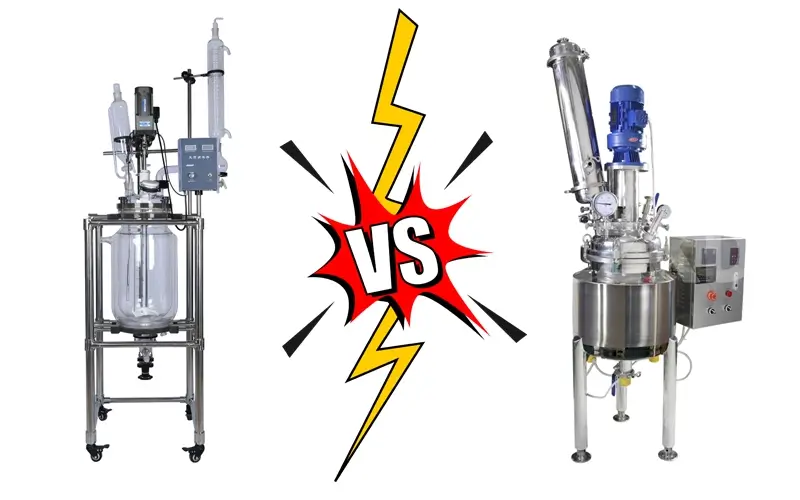

When Should You Choose a Glass-Lined Reactor Over a Stainless Steel One?

Choosing between reactor types can be confusing. Do you need the versatility of stainless steel or the superior chemical resistance of glass? Making the wrong choice can lead to failed experiments.

Opt for a glass-lined reactor when handling highly corrosive substances (like strong acids) or when product purity is critical, as glass is inert. Choose a stainless steel reactor for high-pressure applications, processes involving strong alkalis, or when better thermal conductivity is the priority.

This is a question I get all the time. I once worked with a startup in the flavor extraction industry. They started with a stainless steel reactor, thinking it was the industry standard. But they were working with highly acidic citrus compounds, and they kept noticing a faint metallic taste in their extracts. Their batches were failing quality control. We switched them to a glass-lined reactor, and the problem vanished overnight. Their product purity shot up, and their business took off. This story perfectly shows the trade-off. While a stainless steel reactor vessel is tough and great for many applications, it has its limits, especially with certain chemicals. Knowing when to use which type is key to success.

Making the Right Decision: A Comparison

To help you decide, I’ve put together a simple table based on what I’ve learned from thousands of customer interactions over the years. This isn't just technical data; it’s practical advice for real-world situations.

| Factor | Glass-Lined Reactor | Stainless Steel Reactor |

|---|---|---|

| Primary Use Case | Handling highly corrosive acids, preventing metal contamination. | General purpose synthesis, high-pressure reactions, alkaline solutions. |

| Corrosion Resistance | Excellent, especially against acids (except hydrofluoric). | Good, but vulnerable to chlorides and certain strong acids. |

| Product Purity | Highest level, as glass is inert and non-leaching. | Very good, but slight metallic ion leaching can occur. |

| Pressure & Temperature | Good for vacuum and moderate pressure. Limited by glass. | Excellent for high-pressure and high-temperature applications. |

| Thermal Shock | More sensitive. Requires gradual temperature changes. | Highly resistant to rapid temperature changes. |

| Cost | Generally higher initial investment due to complex manufacturing. | More cost-effective for standard applications. |

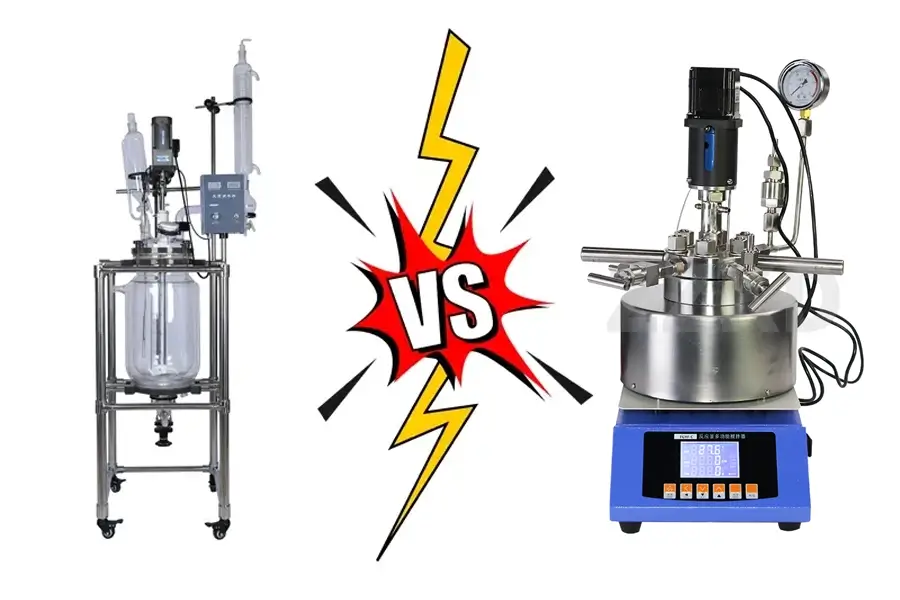

What Are the Key Differences Between Glass-Lined and High-Pressure Reactors?

Your research requires extreme conditions. You know you need specialized equipment, but the line between a standard reactor and a high-pressure one isn't always clear, leading to safety risks.

The main difference is their build and purpose. A glass-lined reactor excels at corrosion resistance under moderate pressure. A high pressure reactor, built from robust metals like stainless steel or Hastelloy, is specifically engineered to safely contain reactions at extremely high pressures.

Think of it like this: a glass-lined reactor is your specialized chemist, perfect for delicate and dangerous materials under normal conditions. A high-pressure reactor is your heavy-duty engineer, built for brute force and extreme environments. We manufacture both, and the choice depends entirely on your process parameters. For example, hydrogenation or polymerization processes often require pressures that a glass-lined vessel simply cannot handle safely. In those cases, a high pressure lab reactor is not just recommended; it's essential. We design these with thick steel walls, specialized sealing mechanisms, and safety features like rupture discs to ensure the reaction stays contained, protecting both the user and the lab environment.

Choosing Based on Application Needs

Your reaction's pressure and temperature dictate your choice. A glass-lined reactor is perfect for distillation, crystallization, and synthesis with corrosive chemicals at or near atmospheric pressure. We have provided many 10L jacketed glass reactor systems for university labs doing exactly this. However, if you're exploring processes that need to push reaction rates by increasing pressure significantly, you must move to a high-pressure system. These systems are also critical in materials science for creating novel materials under extreme conditions. Safety is the number one priority here, and that starts with selecting a vessel specifically designed and rated for the forces you plan to unleash.

Conclusion

Choosing the right reactor—glass-lined, stainless steel, or high-pressure—is crucial for your process safety, purity, and success. Match the equipment to your specific chemical and physical needs.