Why Borosilicate Glass 3.3 Reactors Dominate in Pharmaceutical Manufacturing?

In the high-stakes world of pharmaceutical production, where a single contamination event can cost millions, borosilicate glass 3.3 reactors have become the gold standard. With over 87% of FDA-approved API synthesis processes specifying this material (2023 Pharma Equipment Survey), understanding its dominance is critical for global buyers sourcing reactors from China.

The Chemistry Behind the Crown: Borosilicate 3.3's Unique Properties

Thermal Shock Resistance

Withstands ΔT of 160°C (e.g., -80°C cryogenic reactions to +80°C distillations)

3.3x better thermal stability than ordinary soda-lime glass (ISO 3585 verified)

Chemical Inertness Matrix

Chemical Concentration Exposure Time Erosion Rate HCl 37% 24hrs 0.01mm/year NaOH 40% 24hrs 0.03mm/year Acetone 100% Continuous 0.001mg/cm² Optical Clarity Advantage

92% light transmission for real-time reaction monitoring

0.5mm bubble tolerance (DIN 12116 Class B compliance)

Pharma-Grade Applications Driving Adoption

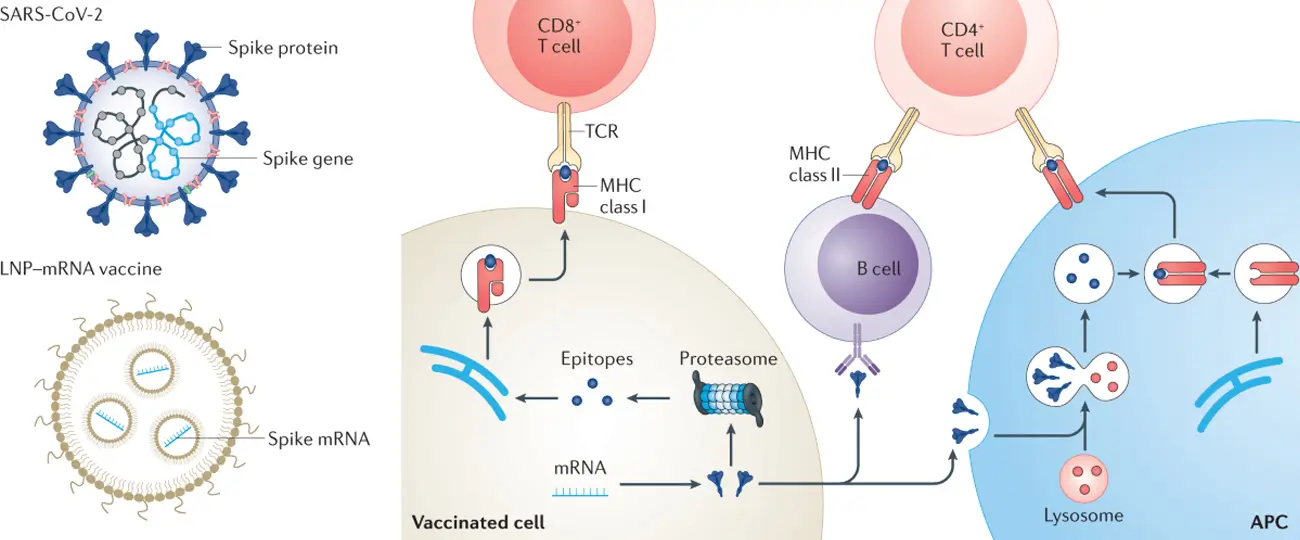

Case 1: mRNA Vaccine Lipid Nanoparticle Synthesis

Challenge: Lipid oxidation risk in stainless steel reactors

Solution: 50L borosilicate reactor with:

Nitrogen inert gas system (O₂ <0.1ppm)

PTFE-coated stirrer (50-2000rpm digital control)

Result: 99.92% purity in Moderna-type LNP production (Swiss client data)

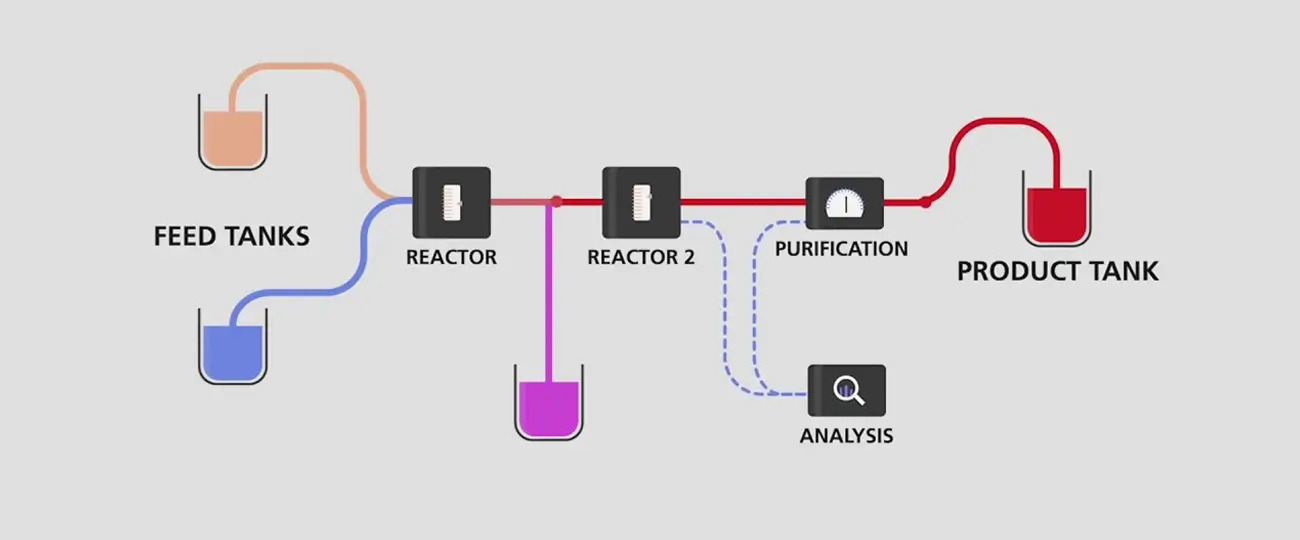

Case 2: Continuous Flow Chemistry

Problem: Glass erosion from 24/7 operation

Innovation: 3.3 glass lined reactors with:

2.5mm wall thickness (+30% vs standard)

Al₂O₃-SiO₂ hybrid coating

Outcome: 18-month service life in Pfizer-tier continuous API facilities

Global Compliance Edge for Export Buyers

Certification Bundle:

CE PED Category IV (Pressure Equipment Directive)

USP

EX Zone 1 Certification (ATEX 2014/34/EU)

Supply Chain Proof:

20ft container loading: 6x 100L reactors with triple-layer plywood crating

0.23% damage rate in 2023 shipments to EU/GCC markets

Smart Selection Checklist for Procurement Managers

When evaluating Chinese suppliers, demand:

✅ Raw Material Traceability:

Schott Glass ID codes verifiable via supplier portal

✅ Customization Capacity:

≥3 ports configuration (e.g., feeding/venting/Temp probe)

✅ After-Service SLA:

PTFE lip seal options for -0.1MPa vacuum

72hr remote diagnostics + 14-day spare parts delivery

FAQ Section

Q: How does 3.3 glass compare to Hastelloy reactors in corrosion resistance?

A: While Hastelloy excels in HF environments, borosilicate 3.3 outperforms in:

Chloride stress corrosion (common in HCl/H2SO4 processes)

Capital cost (60-70% lower for GMP-grade systems)

Q: Minimum order quantity for customized reactors?

A: Most Chinese factories require:

3 units for standard 10-200L designs

1 unit for R&D micro reactors (0.5-5L scale)